Design standard of exhaust slot

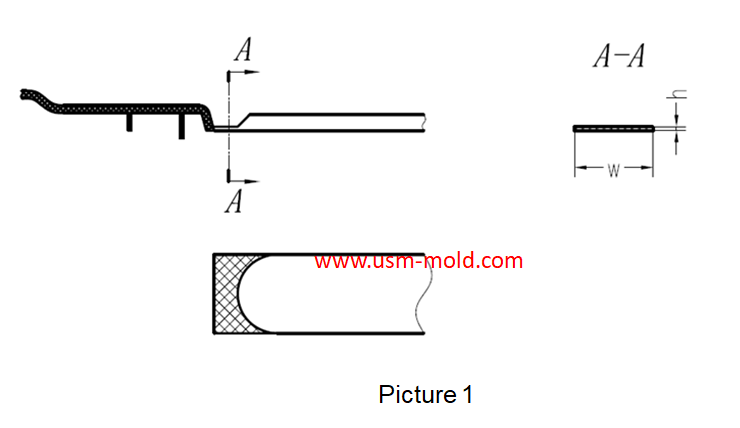

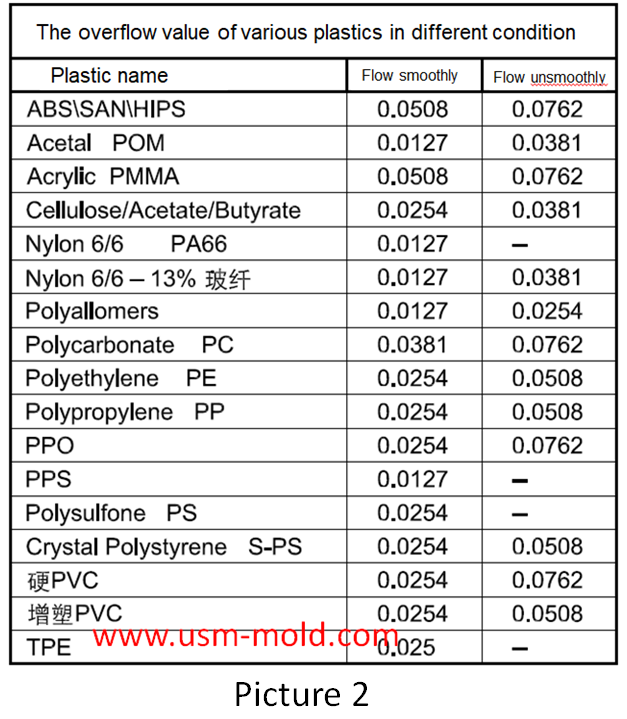

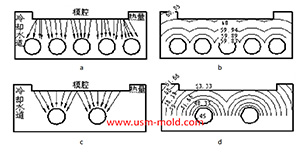

The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage of the gas channel during mass production, most plastic mold factories and plastic mold suppliers only know that they need to open an exhaust slot, but they don’t how large is reasonable. So the cross-sectional size design at the entrance of the exhaust system is very important, in order to meet the above requirements, the inlet section of the exhaust system is usually designed as a gap with a larger aspect ratio (h/w) (see pictue 1), and the gap depth (exhaust gap or exhaust slot depth) h, which is less than the overflow value of the material into the mold is limited, generally 0.02-0.05mm; the gap width w is determined according to the gap depth H and the cross-sectional area A of the exhaust passage required to discharge the gas in the mold cavity during the filling time (w≥A /h).

The cross-sectional area A of the exhaust channel is calculated as follows: A=0.05V/N

In the formula: A exhaust channel cross-sectional area mm²

V—total volume of cavity and pouring system, cm³

n——the number of exhaust slots

The overflow value is the smallest gap that the material can flow into, the overflow value of the molding material depends on the fluidity of the material determined by the material characteristics and process conditions. The better the fluidity, the smaller the overflow value, tThe overflow values of commonly used plastics and conventional molding conditions are shown in picture 2 in the following table.

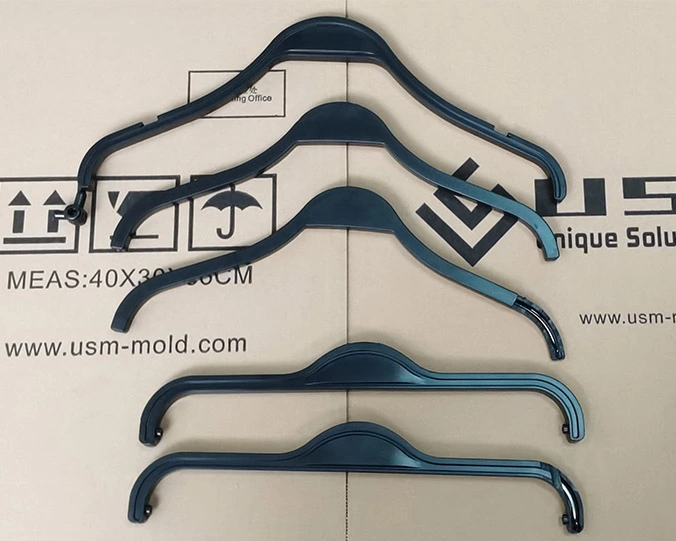

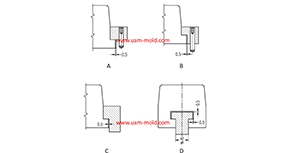

Picure 3 shows the design standard of the exhaust slot, and picture 4 shows the wrong opening method of the exhaust slot.

Plastic injection mold heating

Feb 16, 2022When the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition,...view

Venting of parting surface

Mar 7, 2022The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...view

Factors affecting the cooling rate of parts by injection molding

Feb 9, 2022It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature...view

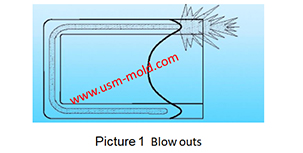

Gas-assisted injection molding product defects and solutions

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

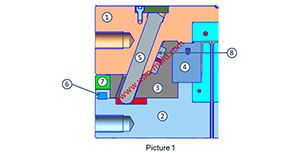

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

Slider of side core pulling mechanisum assembling

Jul 21, 2022The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism. 1. Lateral forming...view

English

English русский

русский

_20250310164515A048.webp)