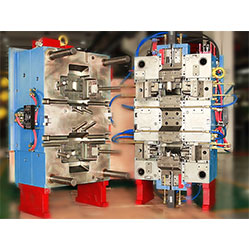

The T slot of slider and guider designing tips

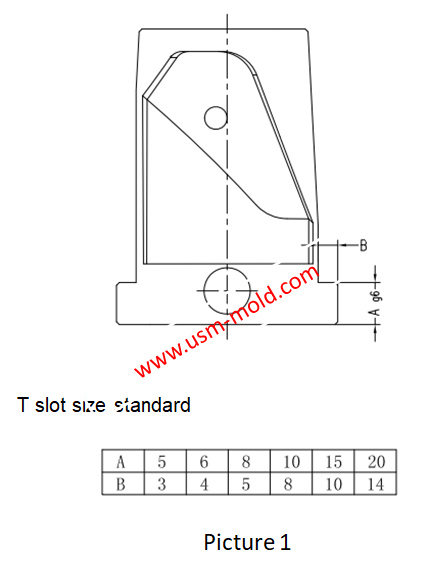

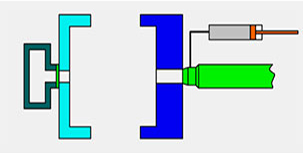

1. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable, so the size A can be made as same as the mold plate after adding the slider holder height;

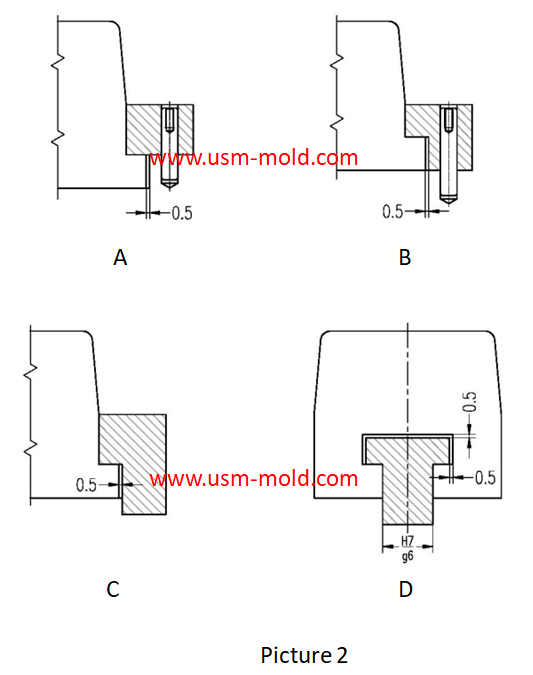

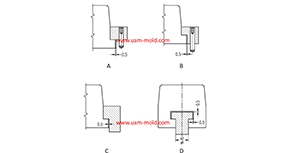

2. There are 4 common types of slider holder which shows in picture 2, it will be better to make the structure of picture 2A;

3 The assembly gap of each slider holder which shows in picture 2;

4. Making at least 2 screws to fix each slider holder, and use 2 dowel pin if there are dowel pins;

5. The friction surface should make oil slot or inserting the graphite between the friction surface of slider holder and slider.

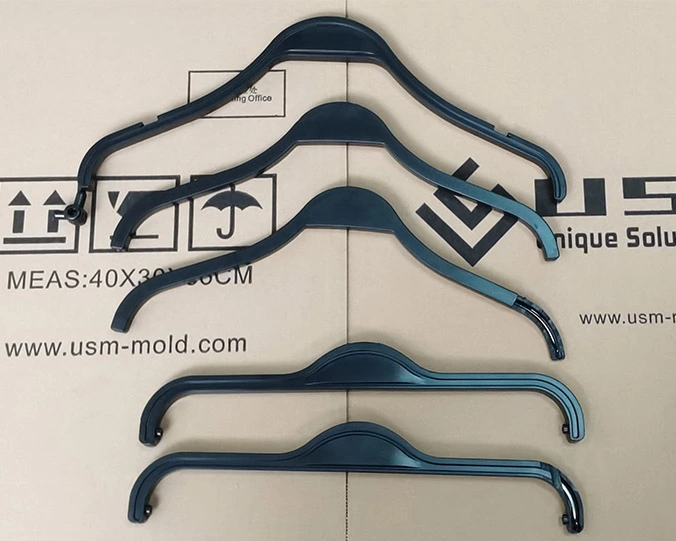

Popular USM Injection Molds

Related News about USM Injection Mold

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

Water assisted injection molding introduction

May 11, 2022Like the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic...view

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

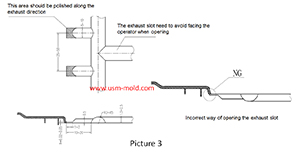

Design standard of exhaust slot

Mar 3, 2022The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...view

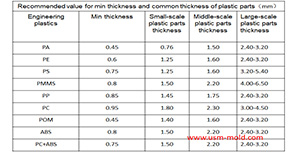

Design principles for wall thickness of plastic products

Jan 3, 2022The principles of wall thickness design for plastic parts are as follows: 1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking...view

English

English русский

русский

_20250311083139A052.webp)