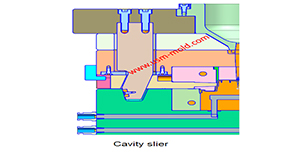

Slider of side core pulling mechanisum assembling

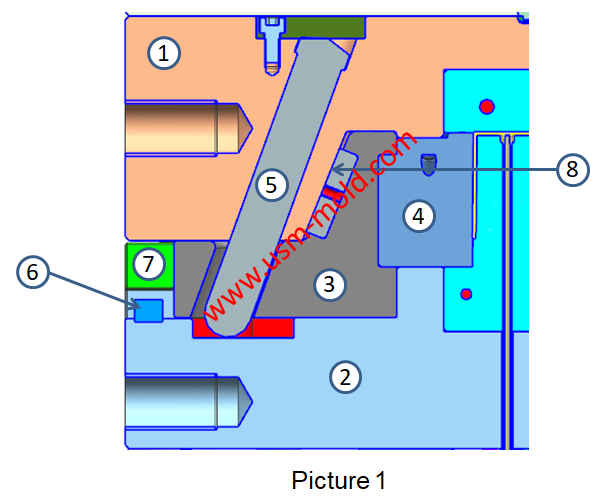

The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism.

1. Lateral forming parts: the lateral forming part is the lateral concavo-convex (including the side hole-shaped parts, including the lateral cores and forming blocks, etc.) of the molded plastic parts, such as the slider insert 4 in picture 1;

2. Moveable parts: moveable parts refer to the parts that install and drive the lateral forming blocks or cores and move inside the guide pin, such as the slider which shows in picture 1;

3. Transmission parts: the transmission parts refer to the parts that drive the moving parts for side parting when the mold is opened or to reset when the mold is drawn and closed, such as the inclined angular pin 5 in picture 1, the types of transmission parts are: dog-leg CAM drive, hydraulic cylinder drive, air cylinder drive, etc.;

4. Locking parts: in order to prevent the moving parts from being displaced by lateral pressure during injection, the parts set are called locking parts, such as the wedge tightening surface 8 in picture 1;

5. Limiting parts: in order to make the moving parts stay in the required position after the side parting or core pulling, to ensure that the transmission parts can be reset smoothly when the mold is closed, the moving parts must be set in the lateral direction, the limit parts at the end of parting or lateral core pulling, such as limit block 6 in picture 1;

6. Guide parts: the guide parts refer to the slider that restricts the slider to move in the correct direction when moving, as shown in the guide rails 7 in picture 2.

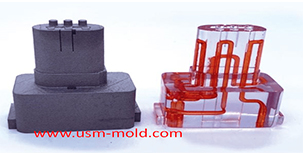

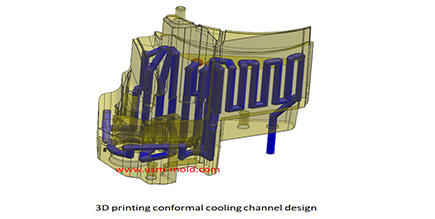

Conformal cooing channel of plastic injection mold

Feb 23, 2022The conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product...view

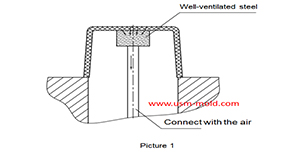

Well-ventilated steel of venting design for molded parts

Mar 14, 2022Well-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow the...view

Design principle of plastic injection mold cooling system

Feb 13, 2022Design principle of cooling system In order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in...view

Venting system of plastic injection mold introduction

Feb 27, 2022Hello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the...view

Reasons for making the exhaust system of the injection mold

Feb 28, 2022The gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in...view

What is the side parting and core pulling mechanisms with their function?

May 31, 2022When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...view

English

English русский

русский