Factors affecting the cooling rate of parts by injection molding

It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature meet the requirements of the molding process. For plastics with high viscosity and poor fluidity, it is necessary to increase the heating temperature and add heating devices in case of difficult molding, due to the low mold temperature.

Importance of mold temperature control system

The mold temperature control and adjustment system affects the quality directly, molding and production efficiency of the part. If the surface temperature of the cavity and core is too high, it is easy to cause flash at the clamping part, and the wall thickness of the plastic part is easy to shrink; if the cavity temperature is too low, it is easy to have defects such as poor filling and insufficient strength at the weld line of the plastic part. If the surface temperature of the cavity and core is uneven, and the temperature difference is large, internal stress will be generated in the molded plastic part, resulting in warpage and deformation after molding, so the mold temperature control system is as important as the gating system, and it is also one of the key to mold design, the design of mold temperature control system should be very careful.

Whether the mold temperature is reasonable is related to the dimensional accuracy, appearance and internal quality of the molded plastic parts, as well as the production efficiency of the plastic parts, so it is an important job in the mold design. Different types of plastics have different temperature requirements for the mold, the general requirement is to make the mold temperature meet the requirements of the process conditions suitable for product molding, and the temperature control system can be adjusted to make the temperature on each part of the mold cavity and core basically the same, the mold temperature should be balanced and consistent in each molding cycle during production process for a long time.

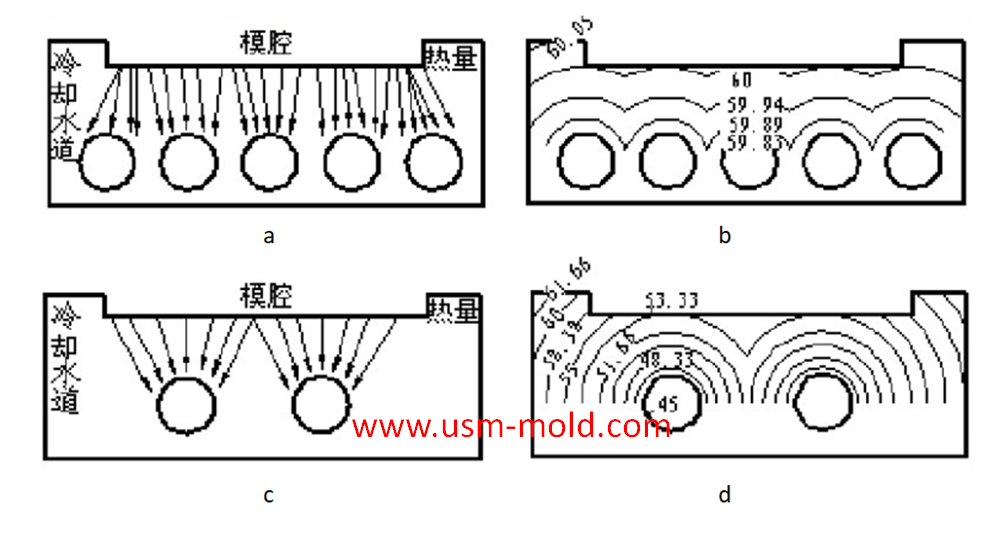

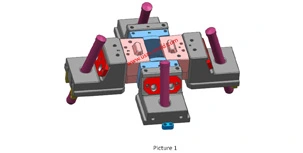

The influence of the cooling water gate of the mold temperature control system on the surface temperature of cavity and core side, the surface temperature of the cavity is relatively uneven and the change of 60~60.05 ℃ when 5 bigger cooling gate are used, it shows in following picture a and b, as shown in following picture C and d, the big temperature difference will cause uneven shrinkage, resulting in warpage and deformation.

The role of mold temperature control system

1. Improve molding performance and shorten molding cycle;

2. Stable part dimensional accuracy and prevent deformation;

3. Eliminate appearance defects and improve the surface quality of plastic parts;

4. Improve the mechanical and physical properties of the product.

USM Blogo Opening

Oct 27, 2021Hello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need. USM is a professional plastic injection mold and molding...view

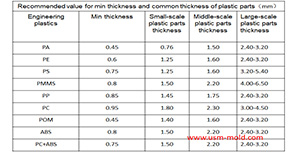

Design principles for wall thickness of plastic products

Jan 3, 2022The principles of wall thickness design for plastic parts are as follows: 1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking...view

Water assisted injection molding introduction

May 11, 2022Like the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic...view

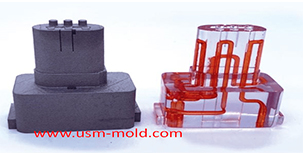

Conformal cooing channel of plastic injection mold

Feb 23, 2022The conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product...view

Plastic molding shrinkage rate

Dec 30, 2021Plastic parts getting smaller by shrink, due to the temperature decrease during the molding process, and the shrinkage is expressed by the shrinkage rate, it is common plastic shrinkage rates are...view

Slider designing tips 2

Nov 22, 20239. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;...view

English

English русский

русский

_20250310164515A048.webp)