Venting of parting surface

The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from the parting surface is very popular by injection mold factory and injection molding plant. If the parting surface is curved or inclined, CNC machining, electrode processing or wire cutting is generally used, the roughness of the parting surface after processing is relatively high, Ra is generally 1.6~6.3μm, and the exhaust slot is generally processed directly by CNC. If the parting surface is flat, it is usually processed by a grinding. The roughness of the parting surface after the grinding machine is low, Ra is 0.2~0.8 μm, the parting surface is tightly fitted, and the gas in the cavity is not easy to discharge. In this case, an exhaust slot must be opened on the parting surface on one side of the cavity. There are two ways to open the exhaust slot on the parting surface: one is to open the exhaust slot locally, and the other is to open the exhaust slot around the part.

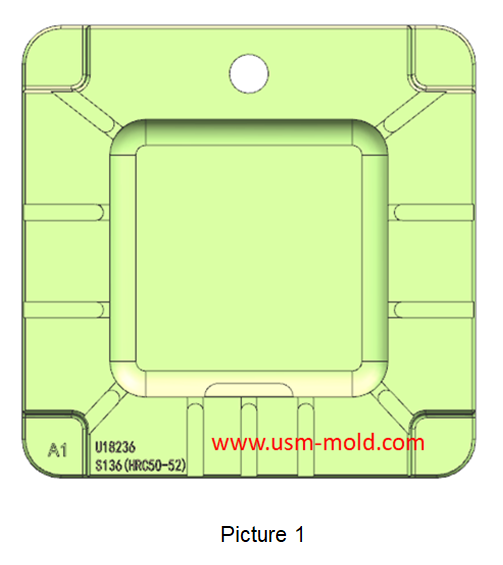

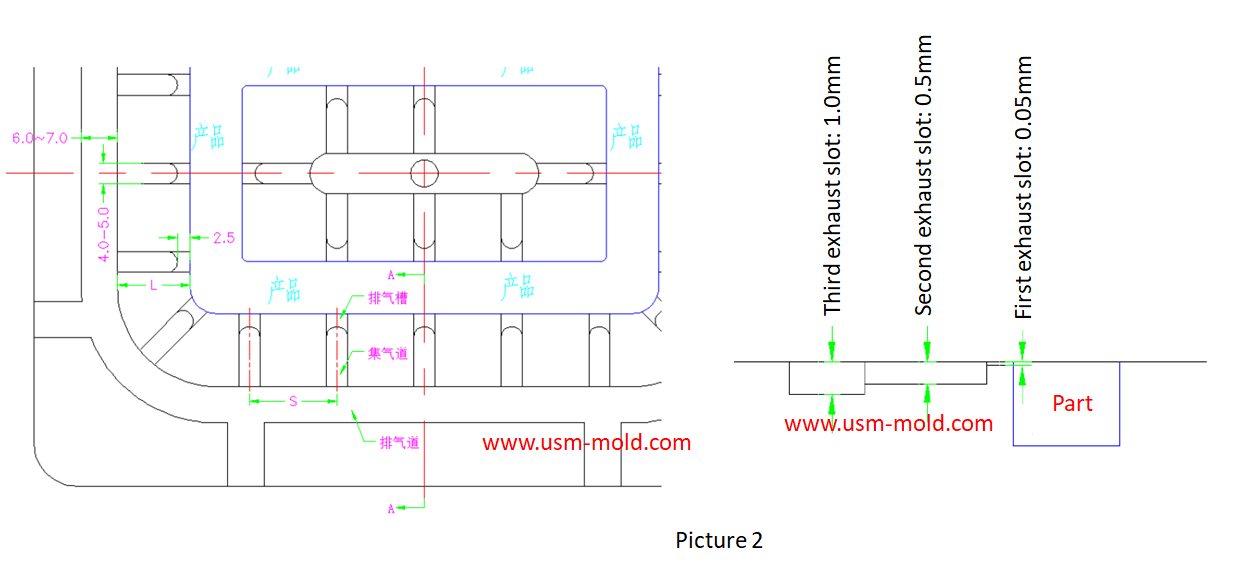

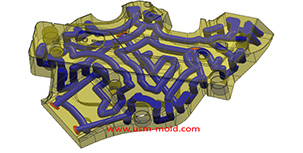

1.Parting surface with partial exhaust slot: this is the most commonly used method of exhaust, the method is to open the exhaust slot where the air is trapped. The position of the exhaust slot is generally combined with the mold flow analysis report based on experience. Determine its final trapped position. This type of venting has less damage to the parting surface of the mold, and it is more flexible and convenient to change the back mold, the specific form is shown in picture 2.

2. Exhaust slot are opened around the parting surface: when the air trap is particularly serious, a large area of exhaust slot can be used to exhaust, as shown in picture 2. If the parting surface of this kind of exhaust slot is flat, it is usually processed with a flat-bottom milling cutter. If the parting surface is curved, it is usually processed with an R-shaped ball cutter, this type of exhaust slot is divided into a first-level exhaust slot, a second-level exhaust slot and a third-level exhaust slot, the depth of which is different.

Gas-assisted Injection Molding Equipment

Apr 10, 2022The gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection...view

Hydraulic diameter conversion of runners in plastic mold gating system design

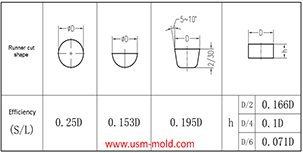

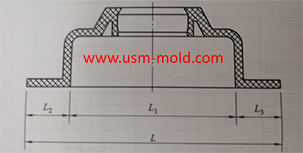

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

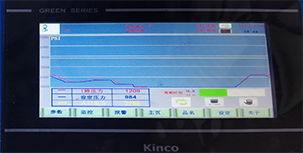

Key points of gas-assisted injection molding process

Apr 20, 2022Gas injection parameters The gas-assisted control part is a device that controls the gas pressure in each stage, the gas-assisted parameters have only two values: gas injection time (seconds) and gas...view

Plastic cooling factors by injection parameter

Feb 10, 20221. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately...view

Plastic molding shrinkage rate

Dec 30, 2021Plastic parts getting smaller by shrink, due to the temperature decrease during the molding process, and the shrinkage is expressed by the shrinkage rate, it is common plastic shrinkage rates are...view

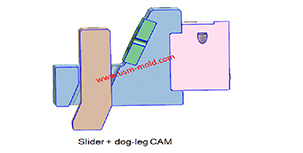

Classification of side parting and core pulling mechanism

Jul 17, 2022According to the structural characteristics of plastic moulding, the side core-pulling mechanisms are divided into the following six categories: 1. The side core-pulling mechanism of "slider + guide...view

English

English русский

русский

_20250310164515A048.webp)

_20250311083139A052.webp)