Unique Solutions Mold Profile

USM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square meters, and has 85 professional and technical workers who have the ability to manufacture 40 sets of medium-sized plastic molds per month, 85% are exported to European and American countries, we are one of the world's leading manufacturers of plastic injection molding and precision molds.

We have been focusing on automatic production, high precision, strict requirements, and quality as our soul to manage the factory, all operations are carried out in strict accordance with the ISO 9001:2015 standard processing, which is higher than the requirements of international standards, strong engineering and design capabilities, and short delivery time and competitive price to provide high-quality products and services for world-renowned companies.

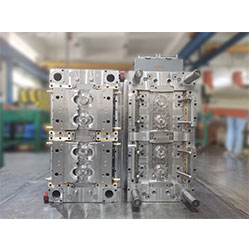

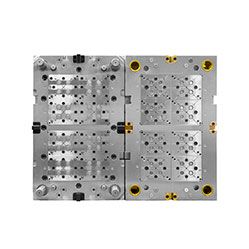

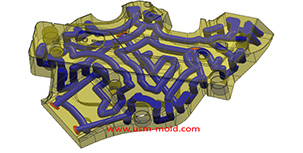

USM is the one-stop service for plastic precision mold and injection molding factory in China, as we know, perfect molds are related to professional mold design, high precision processing machines, rich experiences assembling workers and team management. There are 7 sets of high-speed MAKINO V33I CNC machines which bought from Japan, and SODICK EDM machine and wiring machine in USM, the mold parts tolerance can be made in ±0.005mm, it is the key point to make the parting line perfectly, and also it can be assembled directly after processing finishing.

A good machine is the premise to make the high precision molds, USM is in a rapid development period currently, we do invest a certain percentage of revenue into the advanced equipment and engineering development each year to ensure that advanced technology and precision always surround USM.

We serve different industries, especially in the fields of water-assisted mold, gas-assisted mold, two-colour mold and pre-deformed mold with professional experience make us stand out in this industry.

USM is a professional one-stop service for a plastic injection moulding company in China, with our rich experience with mold making capabilities, we ensure that mass products can be manufactured in the shortest time. There are 15 sets of plastic injection molding machines in our workshop, from 80T to 480T with the automated robot to ensure continuous and stable mass production, The weight of injection molded products ranges from 18 grams to 2000 grams. We provide 24 hours a day & 7 days a week automatic production service.

Not only we can produce over-plasticized equipment, double colour (2K parts) and insert molding, but also we have 4 sets of gas-assisted injection molding production equipment that can produce gas-assisted injection parts too.

Professional technology, fast response, reasonable delivery, one-stop service and exceeding customer expectations are the main factors for USM's success.

"Contribute to your success“, looking forward to providing our service and products for you!

The air trapping position in cavity and exhaust method

Mar 2, 2022The air trapping in cavity is usually in the following places: 1. Thin-wall structure cavity, the end of melt flow; 2. The junction of two or more melts; 3. The last area where the melt in the cavity...view

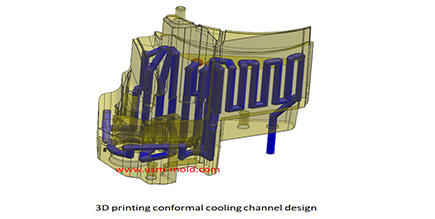

Design principle of plastic injection mold cooling system

Feb 13, 2022Design principle of cooling system In order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in...view

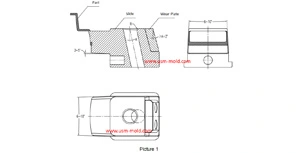

Slider angle designing tips

Dec 4, 20231. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...view

Plastic cooling factors by injection parameter

Feb 10, 20221. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately...view

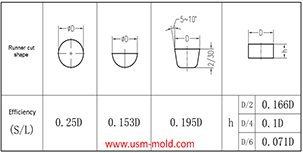

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

Water assisted injection molding introduction

May 11, 2022Like the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic...view

English

English русский

русский