Slider spring hength and strength calculation

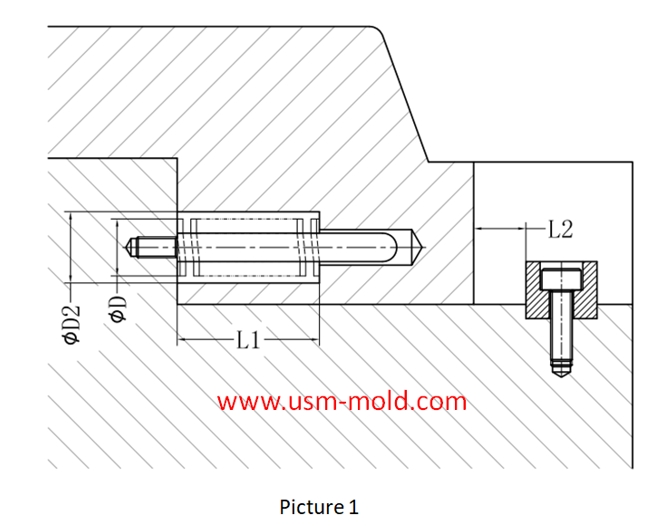

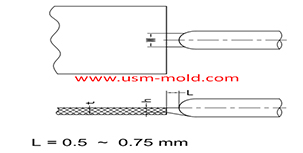

Processing size:

1. ØD2=ØD+2

2. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2)

Spring length calculation: (refer to picture 1 for length calculation)

★L≥H/(36%(compression percentage)-10%(pre-compression percentage)

Assuming the core pulling distance (L2)=15m, the total length of the spring L≥15/(36%-10%)=15/0.26=57.7

As we can see that the total length of the spring (L) should be taken as 60mm

Spring hole depth L1=L-L*10%-L2=60-60*10%-15=39mm

Strength requirements of the slider spring:

1. When the spring is applied to the core pulling of the slider, the load strength must be checked;

2. The weight of the slider on the top side must be kept within 2/3 of the maximum load of the spring; the weight of other sliders must be kept within the maximum load of the spring;

3. When the same slider uses multiple springs, the maximum spring load of the slider is the sum of the loads of all springs;

4. When calculating the maximum load of the slider spring, the compression amount should be in the pull-out state of the slider;

The spring load is calculated as follows:

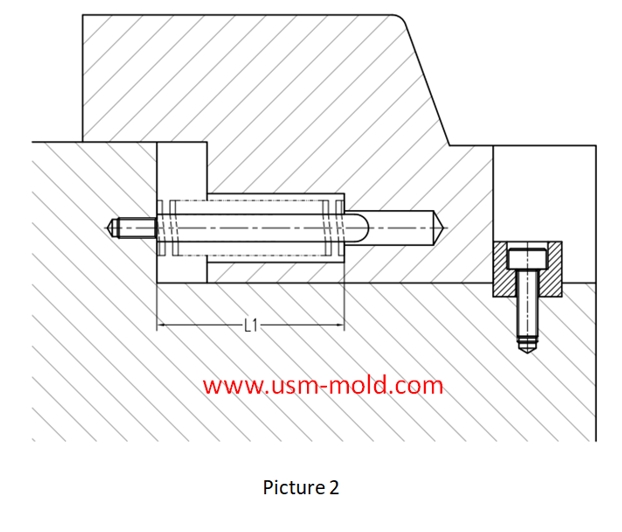

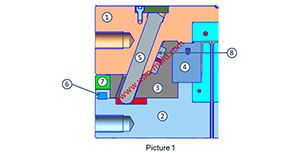

Picture 2:

1. The slider is in the extracted state, so the length of the spring after being compressed is L1;

2. Assume that the free length of the spring is L;

Calculation way of spring load: load = spring constant X compression

That is: load = spring constant X (L-L1)

The spring constant can be obtained from the standard parts data of the corresponding brand (such as MISUMI);

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

Banana gate of plastic injection mold runner system design

Feb 7, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Plastic injection mold runner system design

Jan 16, 2022The gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate...view

Slider of side core pulling mechanisum assembling

Jul 21, 2022The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism. 1. Lateral forming...view

Water assisted injection molding introduction

May 11, 2022Like the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic...view

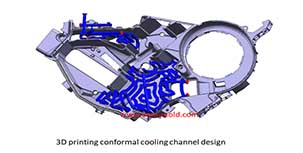

Controling method of plastic injection mold temperature

Feb 15, 2022Except for heat radiation and heat convection from the mold, most of the heat bring into the mold by the plastic needs to be taken out of the mold by the circulating heat transfer medium by heat...view

English

English русский

русский