Side gate of plastic injection mold runner system design

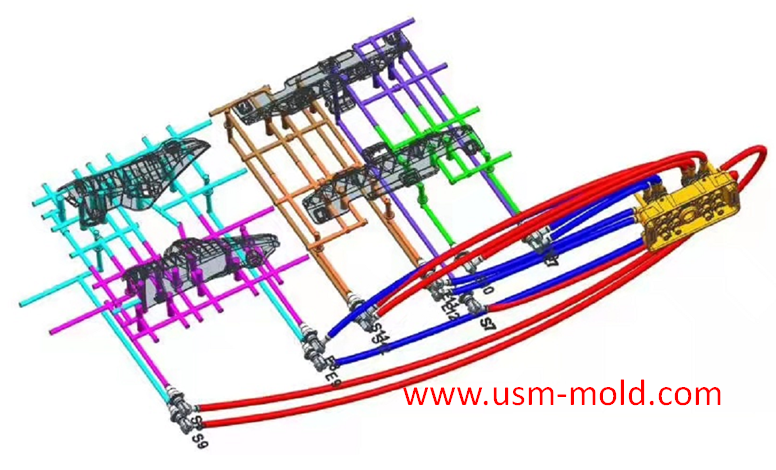

In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among them, the side gate is divided into tab gate, ear protection gate, fan gate, thin gate and so on, the sub gate is divided into sub gate, banana gate, downturning gate and so on.

According to the production automation, it is divided into manual removal and automatic removal, the side gate and direct gate are need to be manually removed after production,but the sub gate and pin-point gate and valve gate of hot runner are automatic removed.

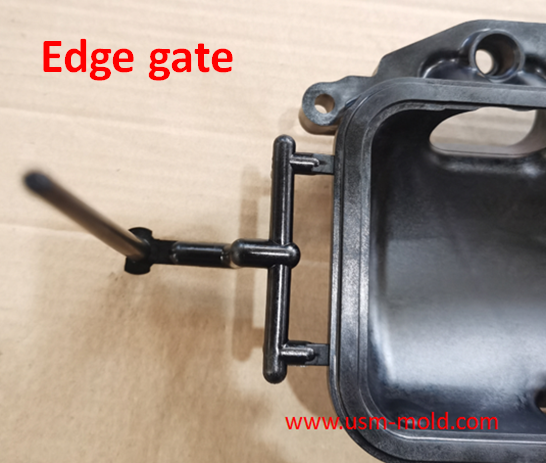

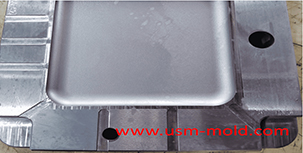

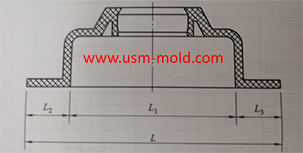

Edge gate: generally make in parting surface of mold, feeding from the edge of the plastic part, the gate cross-section is generally rectangular, as shown in picture 1. The depth of the side gate determines the condensing elbow of the gate, the gate thickness depth is generally 0.5-0.75 times then the wall thickness, and some have the same thickness as the wall thickness, which is generally determined according to the injection volume of the plastic part.

The side gate is the most widely used gate, suitable for various shapes of products, but not suitable for thin and long cylindrical products.

Advantages of side gate:

1. The gate is easy to separate from the part, it is generally in the non-critical surface of part, because the gate thickness is thinner than the wall thickness of the product, so it is more convenient to remove, when the part take out from the mold nand not cooled enought, it can be removed by hand or pliers;

2. It can prevent the plastic from flowing backward, the size and thickness of the side gate are relatively small, after the pressure is maintained during injection molding, the gate position is faster to solidify, so the plastic in the thicker glue position in the product is not easy to flow back through the gate;

3. Frictional heat is generated at the gate, which can raise the temperature of the plastic again and promote filling;

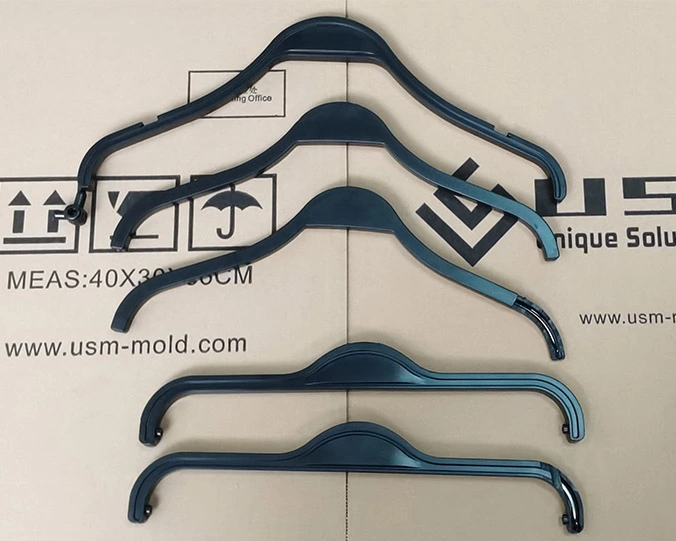

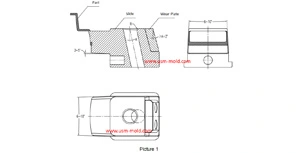

4. The tab gate (as shown in picture 2) can effectively prevent product flow marks;

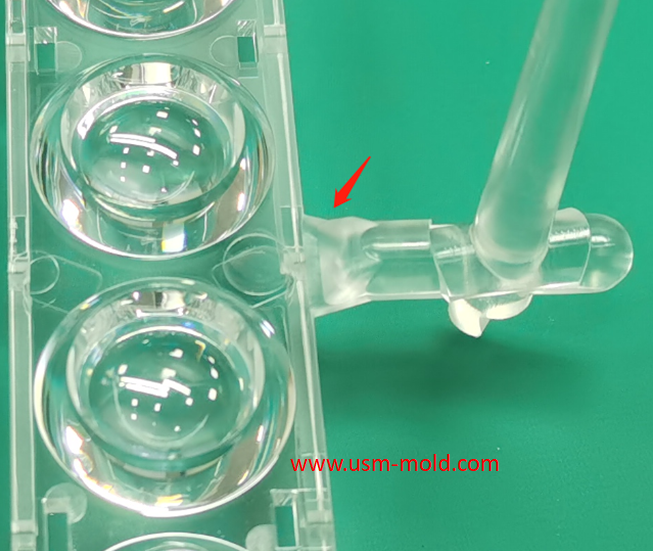

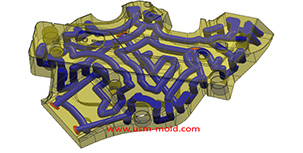

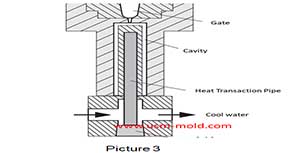

5. Fan gate (as shown in picture 3) can be filled evenly to prevent product deformation, the plastic melt flows smoothly into the cavity without flow marks and weld marks, and the molding quality is good;

6. It is convenient to process the gate, the side gate can generally be processed by CNC directly, EDM can be used for high mold cavity and core.

Disadvantages of side gate:

1. Pressure loss too much, the plastic pass from the main runner, the runner, and the sub- runner before reaching to the gate area, the injection pressure loss too much, due to the side gate is normally make in side of part;

2. Plastic with insufficient fluidity is easy to cause insufficient filling or shutting down;

3. The gate needs to be removed manually, which cannot realize fully automated production;

4. There will be a mark on the edge of the part after moving the gate, which is not suitable for products with high appearance requirements.

Temperature system of injection mold

Feb 8, 2022Hi everyone,the mold cooling time is the longest during injection, so the design of mold temperature system controlling is very important, we will talk about mold cooling, heating system in following...view

Venting system of plastic injection mold introduction

Feb 27, 2022Hello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the...view

Slider angle designing tips

Dec 4, 20231. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...view

Plastic cooling factors by injection parameter

Feb 10, 20221. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately...view

Plastic injection mold common cooling gate

Feb 17, 20221. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing....view

Plastic molding shrinkage rate

Dec 30, 2021Plastic parts getting smaller by shrink, due to the temperature decrease during the molding process, and the shrinkage is expressed by the shrinkage rate, it is common plastic shrinkage rates are...view

English

English русский

русский