The common fixing method of angle pin

The angle pin is a common part of the drive slider, and the fixing and installation methods as following:

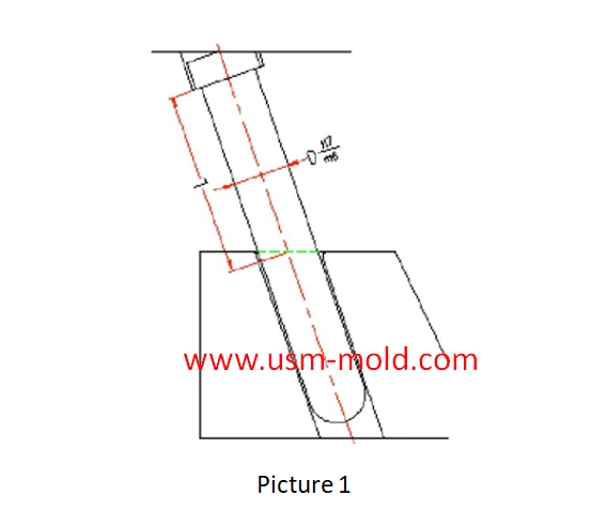

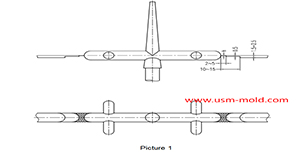

1. Pass through the mold plate directly and press the angle pin with the top plate to fix it, as shown in picture 1.

This installation method is suitable for the case where the formwork is thin and the tope plate is not separated from the A plate, the matching surface is long and the stability is good, the matching tolerance of the angle pin and the fixed plate is H7/m6, disassembly and maintenance are very complex, the mold plate must be disaasembled when changethe angle pin.

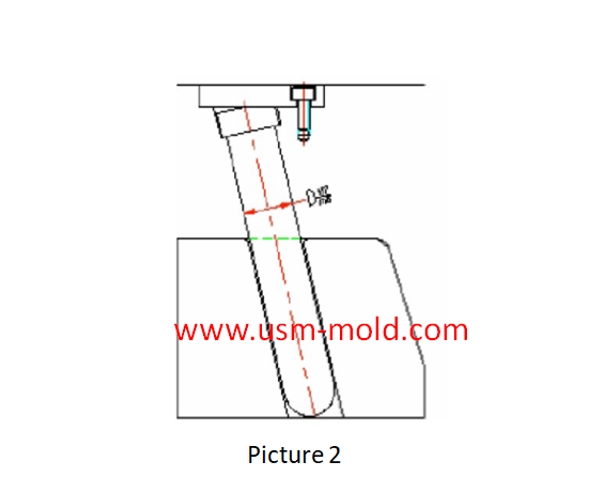

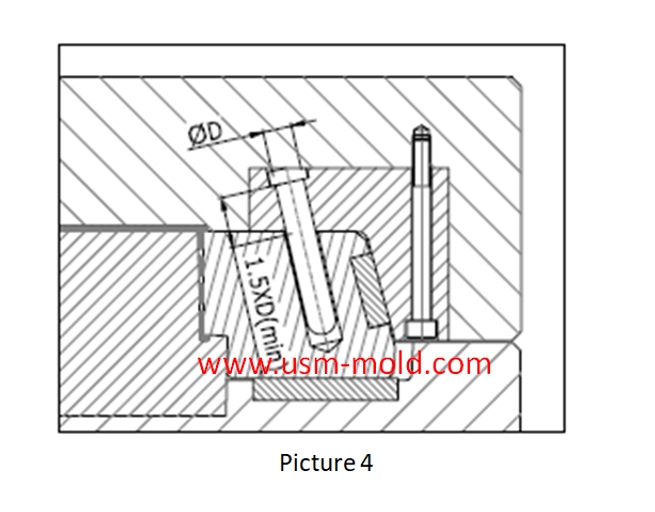

2. Pass through the template directly and press the angle pin with the pressing block to play a fixed role, as shown in picture 2.

This installation method is suitable for the case where the formwork is thin and the top plate is separated from the A plate, the matching surface is long and the stability is good, the matching tolerance of the angle pin and the fixed plate is H7/m6, installation and maintenance are very complex, and the plate must be disassembled to replace the angle pin.

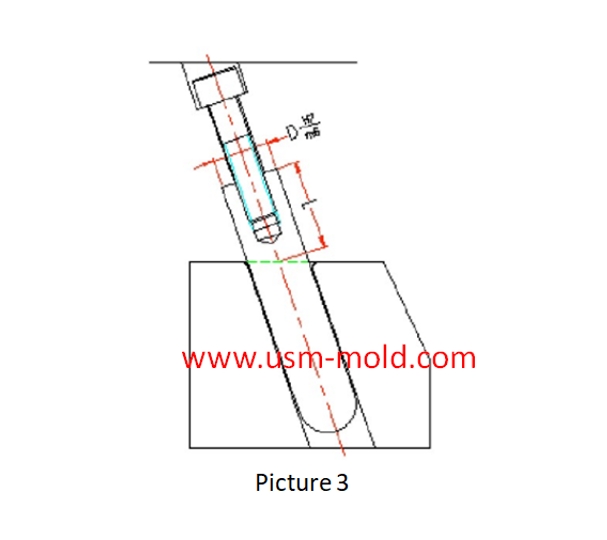

3. The angle pin does not pass through the plate, and the angle pint is still fixed on the plate, but the hole for fixing theangle pin is a blind hole, and a screw is used at the back to tighten the angle pin, this kind of angle pin has no steps, as shown in picture 3.

This installation method is suitable for use in the case of thick plate, and both two-plate and three-plate mold can be used, and the mating surface L needs to be bigger than 1.5D, this installation method has poor stability, and is difficult to process and maintain in the future.

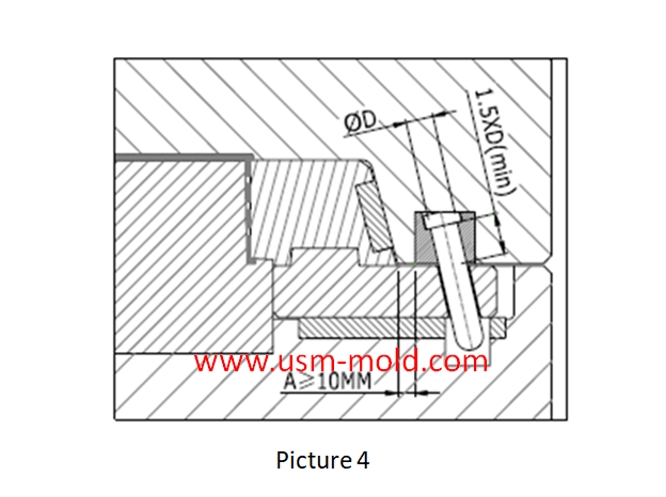

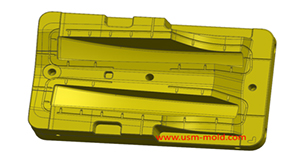

4. The angle pin is not installed in the plate, but is installed in a movable block which is fixed to the plate from the front with screws, the movable block can be disassembled from the front of the plltae, see the picture 4.

This installation method is suitable for use in the case of thick plate, both two-plate with three-plate mold can be used, and the mating surface L needs to be bigger than 1.5D, this installation method has good stability, and is very convenient for processing and maintenance, it is a more common used installation method.

5. The angle pin is not installed in the plate, but is installed in the locking block, this locking block is fixed to the plate from the front with screws, the locking block can be disassembled from the front of the plate, as shown in picture 5.

This installation method is suitable for use in the case of thick plate, both two-plate and three-plate mold can be used, and the mating surface L needs to be bigger than 1.5D, this installation method has good stability, and is very convenient for processing and maintenance, it is also a more common used installation method.

USM Blogo Opening

Oct 27, 2021Hello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need. USM is a professional plastic injection mold and molding...view

Parting surface venting of runner system

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view

Venting system of plastic injection mold introduction

Feb 27, 2022Hello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the...view

The design principle of the exhaust slot

Mar 6, 2022The exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product...view

Plastic injection mold heating

Feb 16, 2022When the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition,...view

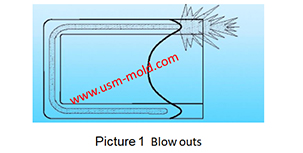

Gas-assisted injection molding product defects and solutions

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

English

English русский

русский

_20250310164515A048.webp)