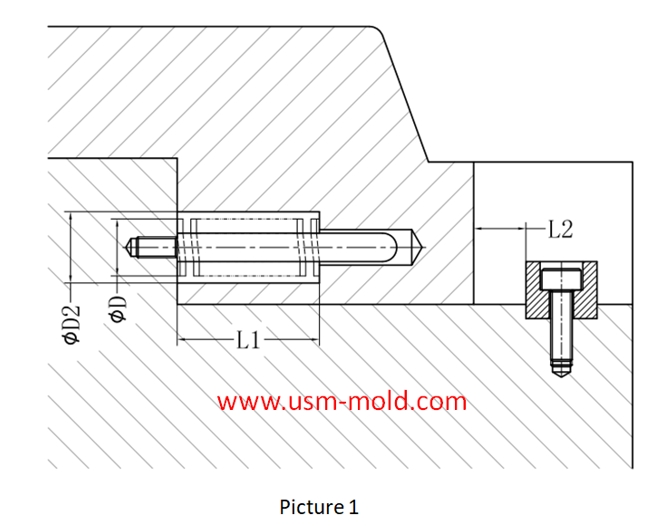

Slider spring hength and strength calculation

Processing size:

1. ØD2=ØD+2

2. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2)

Spring length calculation: (refer to picture 1 for length calculation)

★L≥H/(36%(compression percentage)-10%(pre-compression percentage)

Assuming the core pulling distance (L2)=15m, the total length of the spring L≥15/(36%-10%)=15/0.26=57.7

As we can see that the total length of the spring (L) should be taken as 60mm

Spring hole depth L1=L-L*10%-L2=60-60*10%-15=39mm

Strength requirements of the slider spring:

1. When the spring is applied to the core pulling of the slider, the load strength must be checked;

2. The weight of the slider on the top side must be kept within 2/3 of the maximum load of the spring; the weight of other sliders must be kept within the maximum load of the spring;

3. When the same slider uses multiple springs, the maximum spring load of the slider is the sum of the loads of all springs;

4. When calculating the maximum load of the slider spring, the compression amount should be in the pull-out state of the slider;

The spring load is calculated as follows:

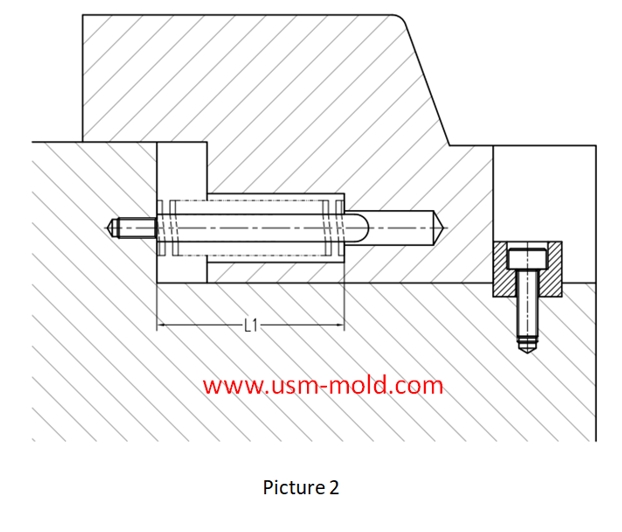

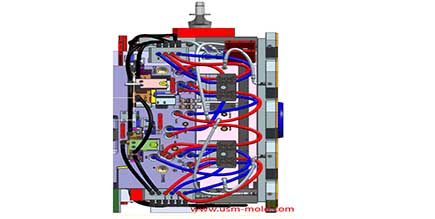

Picture 2:

1. The slider is in the extracted state, so the length of the spring after being compressed is L1;

2. Assume that the free length of the spring is L;

Calculation way of spring load: load = spring constant X compression

That is: load = spring constant X (L-L1)

The spring constant can be obtained from the standard parts data of the corresponding brand (such as MISUMI);

Factors affecting the cooling rate of parts by injection molding

Feb 9, 2022It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature...view

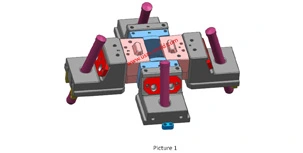

Slider designing tips 2

Nov 22, 20239. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;...view

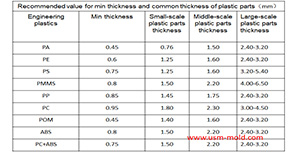

Design principles for wall thickness of plastic products

Jan 3, 2022The principles of wall thickness design for plastic parts are as follows: 1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking...view

Plastic injection mold cooling system design notice

Feb 14, 2022Design notice of designing the cooling system: 1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer; 2....view

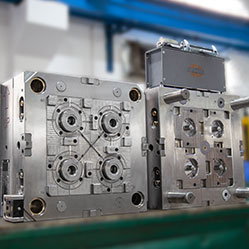

Five Major Steps of the Injection Mold Production Process

Dec 9, 2021Injection mold manufacturing can be roughly divided into the following steps: Process analysis of plastic products. Before the mold design, the designer should fully analyze and study whether the...view_20250317091228A019.jpg)

Main application of gas-assisted molding technology

Apr 7, 2022Gas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the...view

English

English русский

русский

_20250310164515A048.webp)