Design principles of plastic injection mold runner system

1. Quality first

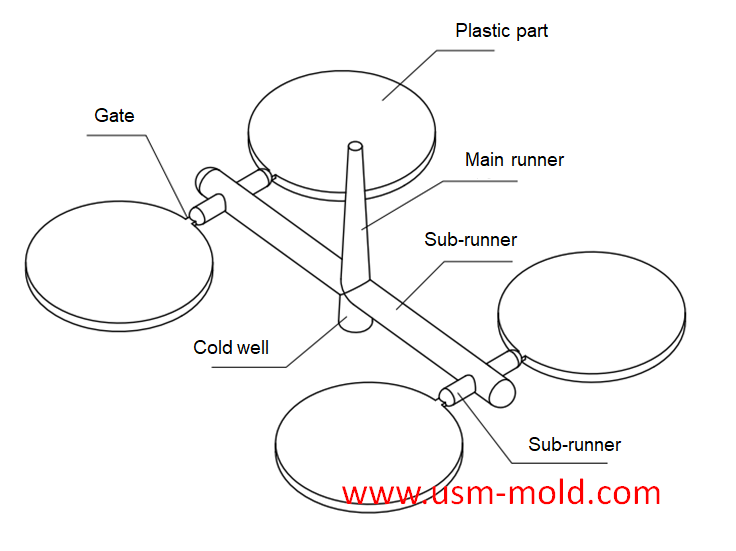

The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the appearance of the plastic part should not be affected as much as possible. Secondly, the gate position and type will directly affect the molding quality of the plastic parts, an unreasonable gating system will cause the defects such as weld marks, poor filling, flow marks, and even lead to the mold failure.

2. Filling balance

In a single-cavity injection mold, the distance between the gate position and each part of the cavity should be as equal as possible, so that the melt fills all corners of the cavity at the same time; in a multi-cavity injection mold, the runner to each cavity should be as equa as possible, so the melt can fill all the cavities at the same time. In addition, the same plastic parts should be feed from the same position to ensure their interchangeability.

3. Smallest volume

The arrangement of the cavities should be as compact as possible, the flow of the gating system should be as short as possible, the cross-sectional shape and size of the runner should be reasonable, and the smaller the volume of the gating system the better, it has the following advantages:

①The less the heat and pressure loss of the melt in the gating system;

②The mold venting is better;

③The mold absorbds the heating less from gating system, the mold temperature control is easier;

④The shorter time of melt flows in the gating system, the mold cycle is shorter;

⑤The less aggregate in the gating system, the less plastic wasted;

⑥The mold size is smaller.

4. Shortest cycle

In the case of a mold with one cavity, it should be ensured that the melt fills all corners of the cavity in almost the same time; when a mold with multiple cavities, it should be ensured that each cavity is filled in almost the same time. In this way, the molding quality of the plastic parts can be guaranteed, and the injection cycle can be minimized. When designing the gating system, we must also try to reduce the resistance of the melt and increase the filling speed of the melt. The runner should reduce the bending, and the arc transition should be used as much as possible when turning. However, in order to reduce the resistance of the melt, it is often not advisable to polish the surface of the runner to a very low roughness, because the appropriate roughness can leave the cold material at the front of the melt on the wall of the runner (runner wall Equivalent to countless miniature cold slug holes). In general, the surface roughness Ra of the runner can be 0.8~1.6μm.

Typical gating system

What is Plastic Injection Mold?

Dec 27, 2021The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and...view

The air trapping position in cavity and exhaust method

Mar 2, 2022The air trapping in cavity is usually in the following places: 1. Thin-wall structure cavity, the end of melt flow; 2. The junction of two or more melts; 3. The last area where the melt in the cavity...view

Gas-assisted Injection Molding Equipment

Apr 10, 2022The gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection...view

Plastic cooling factors by injection parameter

Feb 10, 20221. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately...view

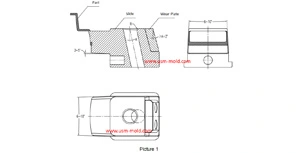

Slider angle designing tips

Dec 4, 20231. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...view

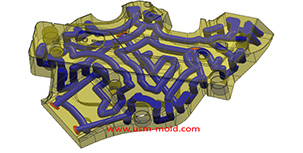

Controling method of plastic injection mold temperature

Feb 15, 2022Except for heat radiation and heat convection from the mold, most of the heat bring into the mold by the plastic needs to be taken out of the mold by the circulating heat transfer medium by heat...view

English

English русский

русский

_20250311083139A052.webp)