Plastic injection mold heating

When the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition, thermoplastic injection molding often needs to heat the mold before molding in the cold winter, because if the weather is too cold, the molten plastic has solidified before being injected into the mold and cannot fill the entire cavity. Thermosetting molds also need heating, heat retention, and pressure retention during the molding process to solidify the raw materials, the mold processing bakelite and the dry press mold for processing Gabu epoxy resin do not have a gating system aggregate, but they need to be heated.

The heating methods of the mold include: hot water, hot oil, steam, resistance heating pipe, etc.

Water and oil heating method:

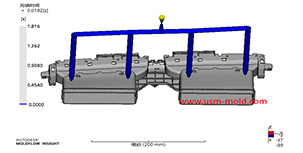

The hot water, hot oil, and steam is also used to heat the mold through the cooling channel in the mold, the mold structure and design principles are exactly the same as the cooling water channel, the use of hot water and hot oil to heat the mold requires supporting equipment, a mold temperature controller, which is widely used in injection molds, and its main functions are as follows:

1. Improving the molding efficiency of plastic parts;

2. Reducing the production of defective products;

3. Improving the appearance quality and reduce the defective of plastic parts;

4. Increasing the production speed, reduce energy consumption and save energy.

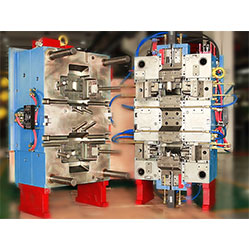

There are two types of mold temperature controllers: water and oil mold temperature controllers (see picture 1 and picture 2).

Features of water temperature controller:

1. The operating temperature range is 40-180℃, accurate to ±1℃;

2. Simple computer touch control operation;

3. Automatic venting;

4. There are display of outlet water and return water temperature;

5. Stainless steel pipes to reduce pipe resistance and rust;

6. The failure is displayed, and the maintenance does not require professionals.

Features of oil temperature controller:

1. The temperature controller adopts touch-type internal storage, automatic calculation, accurate and reliable, and can be controlled within ±2℃, saving more than 35% of electricity;

2. Two sets of electric heating pipes can be used individually or together;

3. The heating and cooling time is fast, and the temperature is stable;

4. The electric heating pipe is made of stainless steel;

5. Perfect safety protection and failure indication system;

6. Imported high-grade components are used, and long service life;

7. Easy to operate and maintain.

water temperature controller

.png)

oil temperature controller

Gas-assisted injection molding product defects and solutions

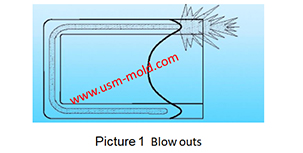

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

Direct gate of plastic injection mold runner system design

Jan 19, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Parting surface venting of runner system

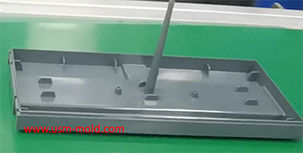

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view

Plastic injection mold runner system design points

Jan 9, 2022When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...view

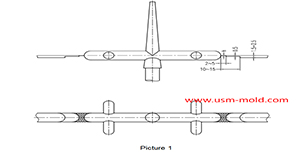

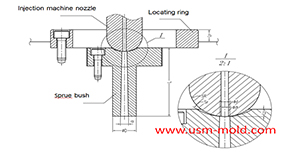

The main design points of the design of the plastic mold pouring system

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

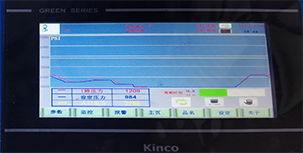

Key points of gas-assisted injection molding process

Apr 20, 2022Gas injection parameters The gas-assisted control part is a device that controls the gas pressure in each stage, the gas-assisted parameters have only two values: gas injection time (seconds) and gas...view

English

English русский

русский