Plastic injection mold runner system design

The gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate directly. The function of the gate is make the molten plastic coming from the runner enter and fill the cavity with core by fast speed, after the cavity with core are filled with plastic, the gate can be cooled quickly and sealed to prevent the hot material in the cavity from flowing material.

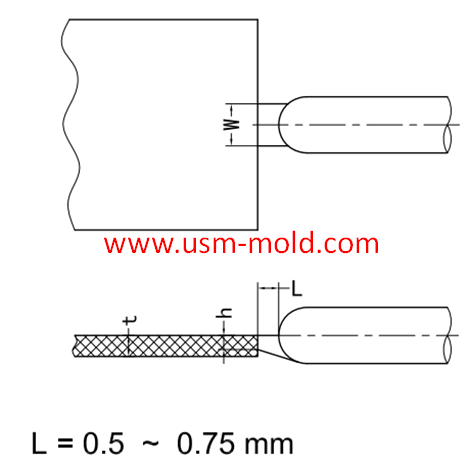

The gate design is related to factors such as the part shape, the cross-sectional size of the part, the plastic performance, the mold structure and the injection process parameters. The gate cross-sectio should be small and the length should be short, so as to increase the material flow speed, fast cooling and sealing to separate the plastic parts, and the gate marks are not obvious.

The gate is a key part of the gating system, the gate location, type and size have a big influence on the plastic parts quality, the quality defects of plastic parts, such as air trapping, shrinkage, water trapping, decomposition, washout, deformation, etc., are often caused by unreasonable gate design. The gate is the smallest part of the entire gating system (except for the direct gate of the sprue type) in many cases.

The design content of the gate includes the following 3 points:

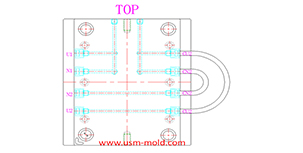

①Select the gate location

②Determine the gate type

③Determine the gate size

We will talk about how to determine the location of the gate in following article.

Five Major Steps of the Injection Mold Production Process

Dec 9, 2021Injection mold manufacturing can be roughly divided into the following steps: Process analysis of plastic products. Before the mold design, the designer should fully analyze and study whether the...view

Different treatment of plastic injection mold cooling system principles

Feb 22, 2022Different treatment principle: 1. The mold temperature is different according to the different plastics, when the plastic requires the molding temperature of the mold to be ≥80°C, the mold must be...view

Banana gate of plastic injection mold runner system design

Feb 7, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Controling method of plastic injection mold temperature

Feb 15, 2022Except for heat radiation and heat convection from the mold, most of the heat bring into the mold by the plastic needs to be taken out of the mold by the circulating heat transfer medium by heat...view

Vacuum venting mold design for plastic molded parts

Mar 23, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

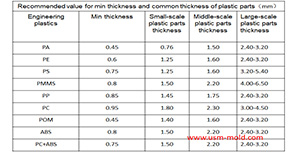

Design principles for wall thickness of plastic products

Jan 3, 2022The principles of wall thickness design for plastic parts are as follows: 1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking...view

English

English русский

русский