The principle of mold temperature balance in plastic mold cooling system design

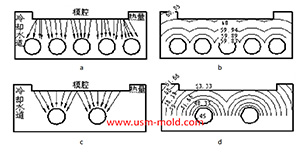

The principle of mold temperature balance:

1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be make the mold temperature as balanced as possible, and there should be no local overheating or overcooling.

2. The high temperature areas in the mold including: near the sprue bushing, near the gate, and near the thick wall of the plastic part, these areas should be cooled.

3. Heating is sometimes required at thin-walled areas.

4. During the cooling process of the mold, due to the phenomenon of thermal expansion and contraction, the plastic part will slightly detach from the fixed mold cavity when the solid shrinks, while the tightening force on the core is getting bigger and biggger, and the plastic part is detaching, the more heat before demolding is transferred to the core, so the core must be focused on cooling.

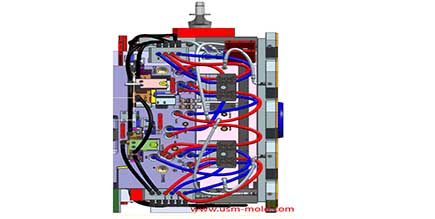

5. To control the temperature difference of the cooling water at the inlet and outlet of the cooling channel, the temperature difference should be less than or equal to 2°C during precision injection molding, and in general, the temperature difference should be less than or equal to 5°C. the total length of the cooling gate (series length) should not be too long, preferably less than 1.5m, and the length of the dead zone should be as short as possible.

6. The cooling channel must be designed for the stripper in the three-plate mold, t, so that the mold temperature can be stabilized during the production process and the molding cycle can be shortened.

.png)

_20250317091228A019.jpg)

Main application of gas-assisted molding technology

Apr 7, 2022Gas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the...view

Banana gate of plastic injection mold runner system design

Feb 7, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Factors affecting the cooling rate of parts by injection molding

Feb 9, 2022It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature...view

Plastic injection mold heating

Feb 16, 2022When the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition,...view

Plastic injection mold cooling system design notice

Feb 14, 2022Design notice of designing the cooling system: 1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer; 2....view

The common fixing method of angle pin

May 10, 2024The angle pin is a common part of the drive slider, and the fixing and installation methods as following: 1. Pass through the mold plate directly and press the angle pin with the top plate to fix it,...view

English

English русский

русский

_20250310164515A048.webp)