The difference between full shot and short shot of gas-assisted injection molding

Gas-assisted injection molding can be divided into short shot and full shot.

- Short shot

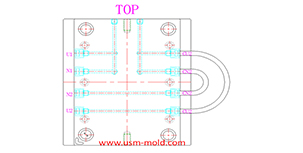

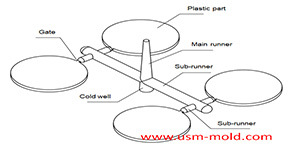

The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling resistance, especially rod-shaped parts, which can save a lot of raw material, we should inject part of resin into the cavity and core (usually only fills 50% volume of caity and core) during the short shot, and immediately inject gas into the center of the resin, push the gas and obtain a hollow plastic part, For thin-walled plastic parts with high mold filling resistance, it’s better to use full shot molding.

For short shots, the percentage and prolong time of plastic melt fills the cavity and core before the gas injected are the main factors to control the length of the gate channel, in addition, the further shrinkage of the plastic will make the channel continue to be longer, if too much plastic is injected at early stage, it will cause the gas flow length is not enough, but if too little plastic is injected, the gas will quickly penetrate the plastic flow front and cause waste.

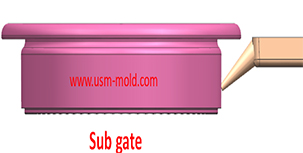

2. Sub-cavity method (full shot)

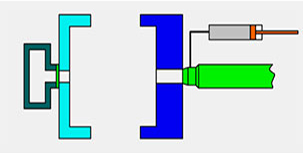

The secondary cavity molding method, it is also called the overflow well method, it is a kind of full shot process (as shown in picture 2). the secondary cavity method requires a secondary cavity that can connect with the mold cavity in outside, the secondary cavity follows the main cavity, the valve needle between the cavities is opened or closed by the hydraulic cylinder or air cylinder, first, close the sub cavity, inject plastic melt into the cavity until the cavity and core is full, then open the sub cavity, and inject gas into the cavity, the penetration of gas pressure causes the excess melt to flow into the secondary cavity, when the gas penetrates to a certain extent, the secondary cavity is closed, and the gas pressure continues to increase to maintain pressure and feed the melt in the cavity with core side, and finally open the mold to eject products.

Different treatment of plastic injection mold cooling system principles

Feb 22, 2022Different treatment principle: 1. The mold temperature is different according to the different plastics, when the plastic requires the molding temperature of the mold to be ≥80°C, the mold must be...view

The sub gate of the plastic injection mold runner system

Jan 26, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Design principles of plastic injection mold runner system

Jan 6, 20221. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...view

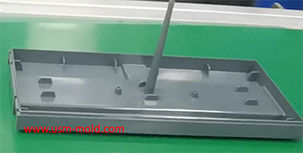

Design principles for wall thickness of plastic products

Jan 3, 2022The principles of wall thickness design for plastic parts are as follows: 1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking...view

Direct gate of plastic injection mold runner system design

Jan 19, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

English

English русский

русский

_20250310164515A048.webp)