Plastic injection mold cooling system design notice

Design notice of designing the cooling system:

1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer;

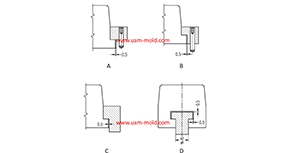

2. Using less sealing ring when design the cooling gate system, and the water pipe is better to be two-way straight, which is convenient for repairing when it is blocked. Note that the seals and faucet pipes are prone to water leakage and water seepage, and the dimensional tolerances of the sealing grooves should meet the requirements;

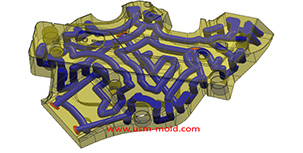

3. When using PE or other materials, because of the big molding shrinkage, the cooling gate should be arranged along the shrinking direction to make the plastic parts not easy to deform. The water channels are arranged longitudinally according to the arrangement direction of the cavity and core;

4. When the mold has only one water inlet and one water outlet, the cooling pipes should be connected in series, if parallel connection is used, the flow resistance of each circuit is different, and it is difficult to form the same cooling conditions. When parallel connection is required, a water volume adjustment device, flow meter and flow meter should be installed in each loop;

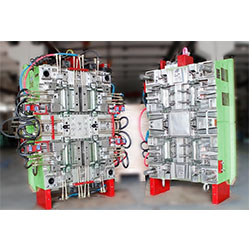

5. If the cooling effect is not good and the structure is restricted by the shape of the structure, in order to improve the cooling effect, consider choosing a material or structure with good thermal conductivity, such as beryllium copper, copper alloy, or a thermal conductive rod structure. The cavity, the core, inserts, and sliders must be cooled by every means if neccessary;

.jpg)

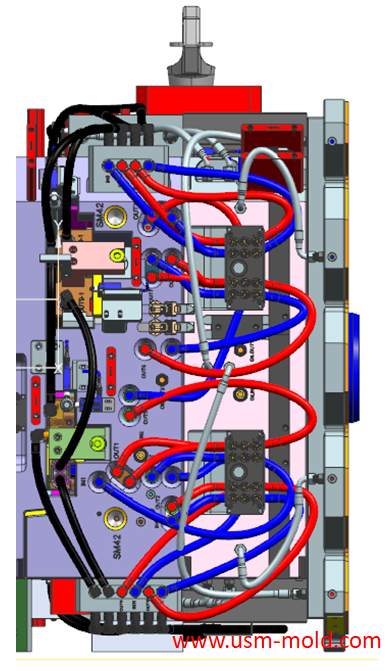

6. The inlet pipe joint area is marked with red, and the outlet pipe joint is marked with blue;

7. In the position near the cooling water inlet and outlet of the cavity with core side, mark the entry "IN" and the exit "OUT" in English; and mark the water gate accordingly.

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

Plastic cooling factors by injection parameter

Feb 10, 20221. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately...view

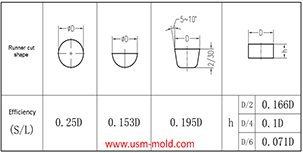

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

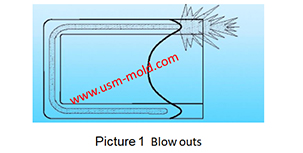

Gas-assisted injection molding product defects and solutions

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

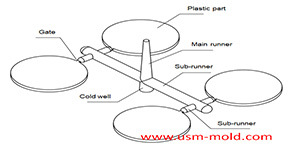

Design principles of plastic injection mold runner system

Jan 6, 20221. Quality first The design of the gating system has a big influence on part quality, firstly the gate should be set at the easiest part of the plastic part to be removed, and at the same time, the...view

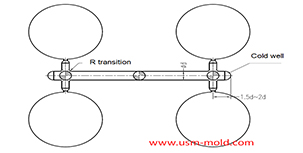

Key points of plastic injection mold runner system

Jan 12, 2022The sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...view

English

English русский

русский