Parting surface venting of runner system

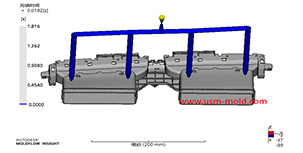

There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting surface, rest of gas will enter the cavity with plastic melt together, but it is better to have less gas inside cavity to reduce the venting cavity.

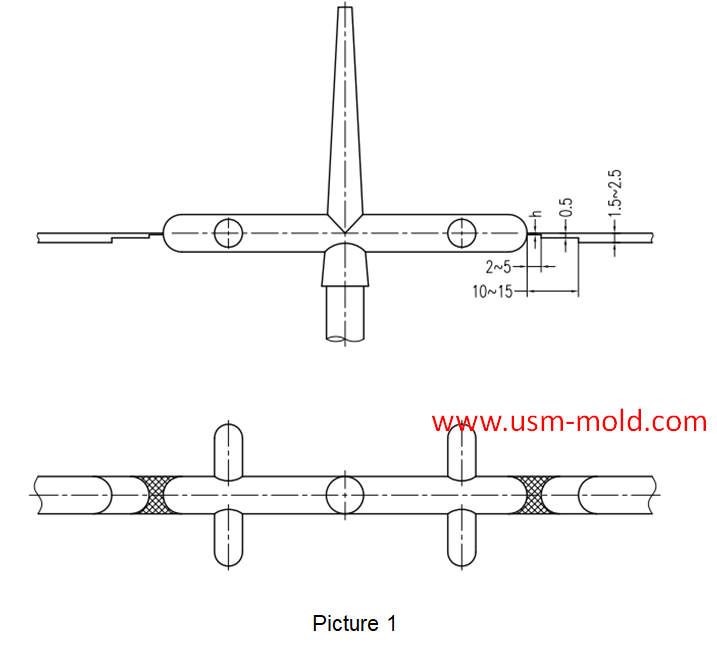

The gas in therunner system should be mainly discharged through the parting surface, the exhaust slot of the gating system is mainly opened at the end of the runner, as shown in picture 1.

The exhaust slot design of the runner:

The depth of the exhaust slot (h) is as deep as the flash edge at the end of the runner;

1. Plastic with good fluidity, h≈0.075mm;

2. Plastic with poor fluidity, h≈0.125m;

The width of the exhaust slot is the same as that of the runner, and the entrance should be polished;

The injection pressure at the runner is high, and the exhaust slot should not be facing the operator.

Limitations of gas-assisted injection molding technology

Apr 25, 2022Gas-assisted injection molding technology has obvious advantages in thick wall thickness and pipe parts, but this technology still has many limitations, which are mainly reflected in the following...view

Direct gate of plastic injection mold runner system design

Jan 19, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Plastic injection mold runner system design points

Jan 9, 2022When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...view_20250317090912A017.jpg)

Several common process of water-assisted injection molding introduction

May 24, 2022According to the design of the injection molding machine and the casting system, the corresponding melt-returning process of water-assisted injection molding can be roughly divided into two types: the...view

Five Major Steps of the Injection Mold Production Process

Dec 9, 2021Injection mold manufacturing can be roughly divided into the following steps: Process analysis of plastic products. Before the mold design, the designer should fully analyze and study whether the...view_20250317091113A018.jpg)

The basic points of designing gas-assisted injection molding

Apr 17, 20221. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel; 2. The gas channel should be arranged in...view

English

English русский

русский