Hydraulic diameter conversion of runners in plastic mold gating system design

Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls, only the average value of the surrounding walls can be calculated.

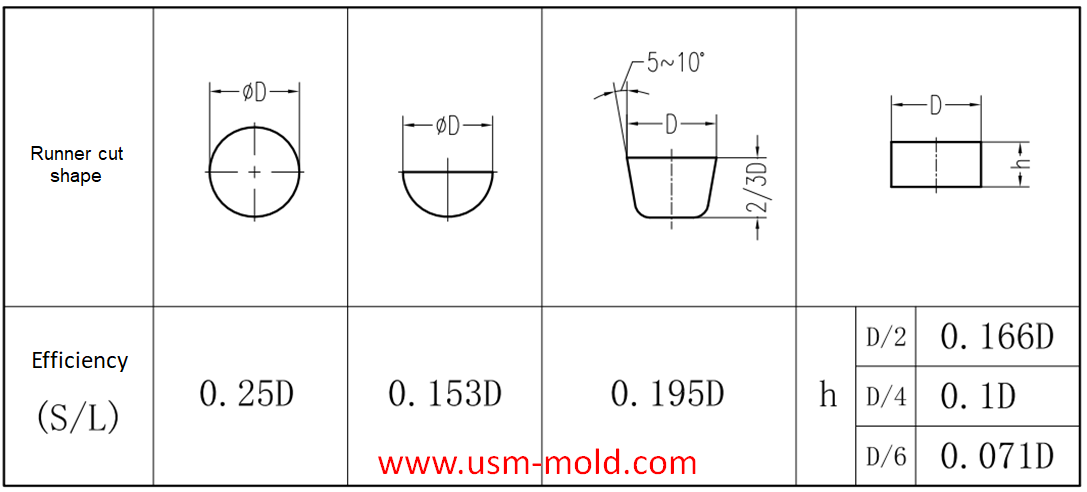

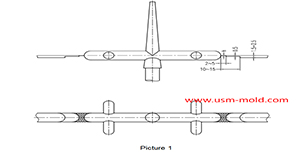

The main cross-sectional shapes of the shunt: round, trapezoidal and rectangular, in order to reduce the pressure heat loss in the runner, the cross-sectional area of the runner should be maximized, and the internal surface area for heat dissipation should be the smallest.

The efficiency of the runner is expressed by the ratio of the cross-sectional area S of the runner to its cross-sectional circumference L.

Splitter efficiency (hydraulic radius) n=cross-sectional area/cross-sectional circumference=S/L

Hydraulic diameter=4n=4S/L

From the above information, we can see the flow efficiency of different cross-section runners, round and trapezoidal cross-sections are the preferred runners. The size of the runner is usually selected based on the diameter of the circular runner (equal to the hydraulic diameter); when other cross-section flow channels are used, the hydraulic diameter must be converted so that the flow efficiency can meet the calculation requirements (see the example below) ).

Example: It is calculated that a product needs a 8m hydraulic diameter runner, and a semicircular runner is now used; what size of semicircle is more reasonable?

Hydraulic diameter=4n=4S/L=(4*(πr²)/2)/(π*r+2r)=8

Radius r=8*(π+2)/(2π)=6.55

Diameter D=2*r=6.55*2=13.1

Answer: A semicircular runner with a diameter of about 13m is more suitable.

Venting system of plastic injection mold introduction

Feb 27, 2022Hello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

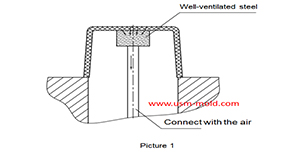

Well-ventilated steel of venting design for molded parts

Mar 14, 2022Well-ventilated steel is a sintered alloy, iIt is a porous material sintered with spherical particle alloys, the pore size is 7-10μm and the strength is poor, but the texture is loose which allow the...view_20250317091228A019.jpg)

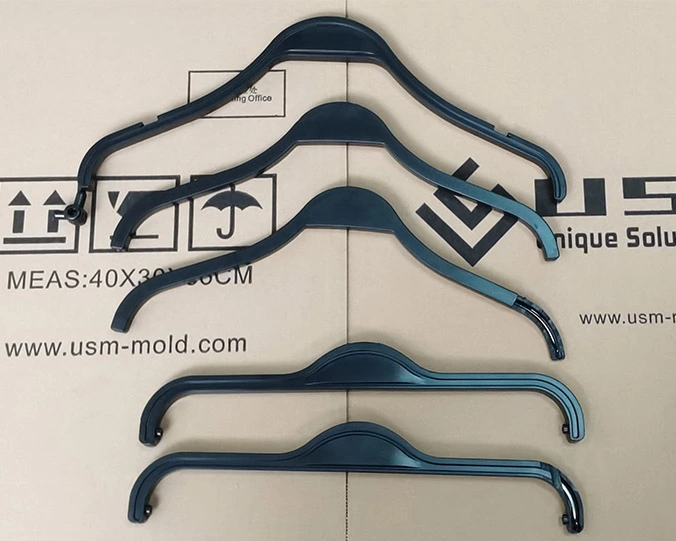

Main application of gas-assisted molding technology

Apr 7, 2022Gas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the...view

Parting surface venting of runner system

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view

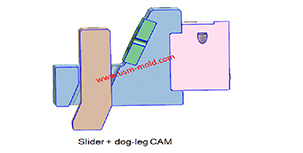

Classification of side parting and core pulling mechanism

Jul 17, 2022According to the structural characteristics of plastic moulding, the side core-pulling mechanisms are divided into the following six categories: 1. The side core-pulling mechanism of "slider + guide...view

English

English русский

русский

_20250310164515A048.webp)