Conformal cooing channel of plastic injection mold

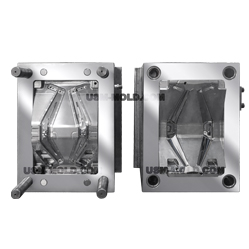

The conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product well, and the cooling gate section can be any section except the round shape.

For the conformal cooling gate mold parts manufactured by 3D printing, the cooling gate can be evenly distributed according to the product shape, thereby further reducing the molding cycle and increasing the value of the product.

.png)

Conformal cooling principle

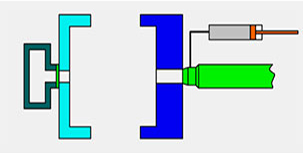

The cooling of plastic products during injection molding is mainly done by the mold cooling gate, but the traditional cooling gate is manufactured by machining processes such as milling machines, the gate can only be a cylindrical straight hole and cannot be completely close to the surface of the injection molded part, the cooling efficiency is low and the cooling is uneven, resulting in a long injection cycle and big product deformation.

The 3D printed conformal cooling gate can be of any shape and any cross section, by changing the shape and cross section, the conformable cooling gate can be evenly arranged to achieve a faster and more even cooling effect.

Advantage

1. According to the complexity of the shape of the injection molded part, the cooling time can be reduced by 20% to 80%;

2. According to the shape of the injection molded part, the deformation can be reduced by 15% to 90%;

3. The mold cost has increased slightly, but the overall efficiency of injection molding capacity, yield and other factors have greatly improved the final benefit;

4. The conformal cooling gate has a wide range of applications and can be used for cooling optimization of most injection molded parts.

.png)

Manufacturing technology

Conformal cooling gate is currently mainly processed by selective laser melting (SLM) 3D printing technology and diffusion welding technology, because SLM 3D printing technology can make more complex and smooth waterway shapes and lower costs, SLM 3D printing technology is in the conformal cooling gate is more widely used.

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view_20250317091113A018.jpg)

The basic points of designing gas-assisted injection molding

Apr 17, 20221. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel; 2. The gas channel should be arranged in...view

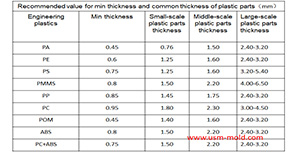

Design principles for wall thickness of plastic products

Jan 3, 2022The principles of wall thickness design for plastic parts are as follows: 1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking...view

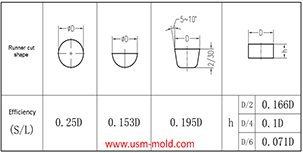

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

The design requirements of slider wear plate

Jan 2, 20241. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...view

Gas-assisted injection molding product defects and solutions

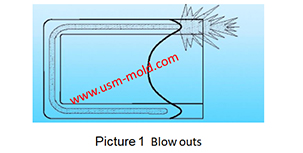

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

English

English русский

русский