Plastic injection mold common cooling gate

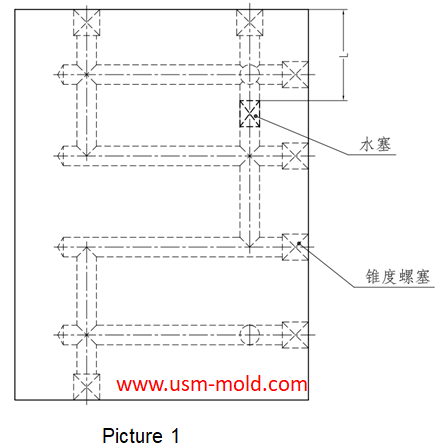

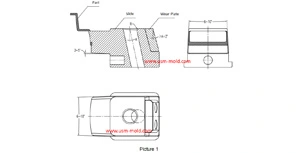

1. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing. It is commonly used on molds with thinner walls and larger areas, which shows in picture 1.

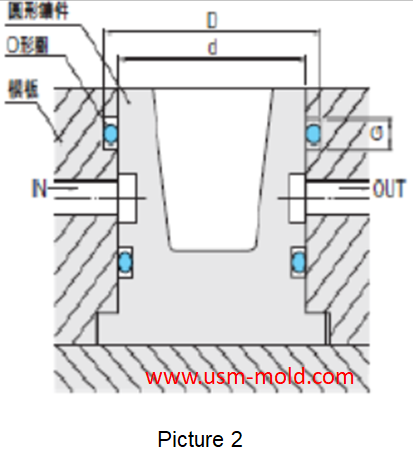

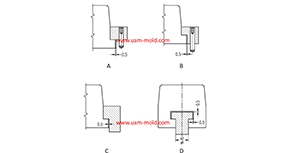

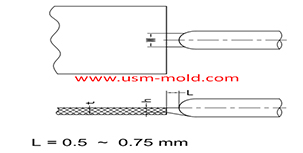

2. Annular cooling water gate: this cooling water gate is suitable for round inserts parts, where there is ejector pin and plastic material in the insert and cannot be used for cooling methods such as water well spraying, the common structure is shown in picture 2, we shold we should try to avoid the sealing ring being worn and worn by the cutting during assembly.

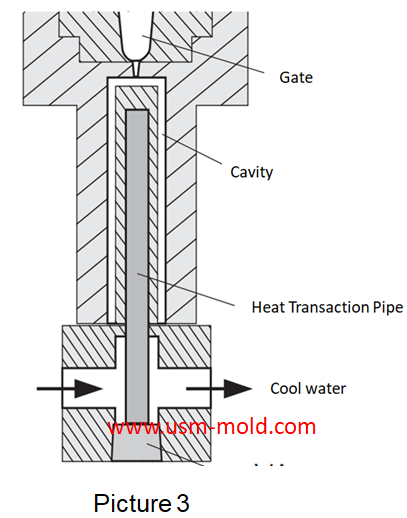

3. Heat conduction rod type: for some slight cores, conventional water transportation, spraying and water well cooling cannot be used, and heat conduction rods can be used to transfer the heat from the melt to the core, and then the cooling water carry out the heat from the mold, as shown in picture 3, the material of the thermal conductive rod is usually beryllium copper.

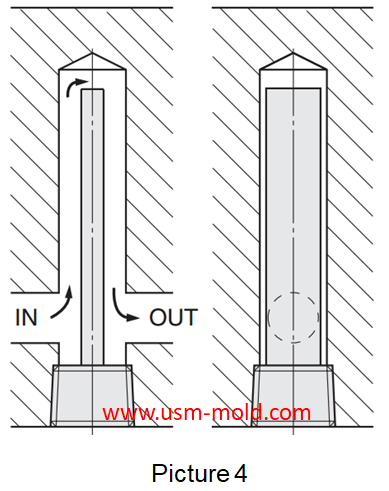

4. Baffle board cooling water gate: the baffle board is often used in deep cavity molds, this type of mold has a large core length and absorbs a lot of heat from the plastic melt, but the width or diameter is small and common, the cooling water gate is often unable to go up, and the ideal effect can be achieved by using a baffle board, as shown in picture 4.

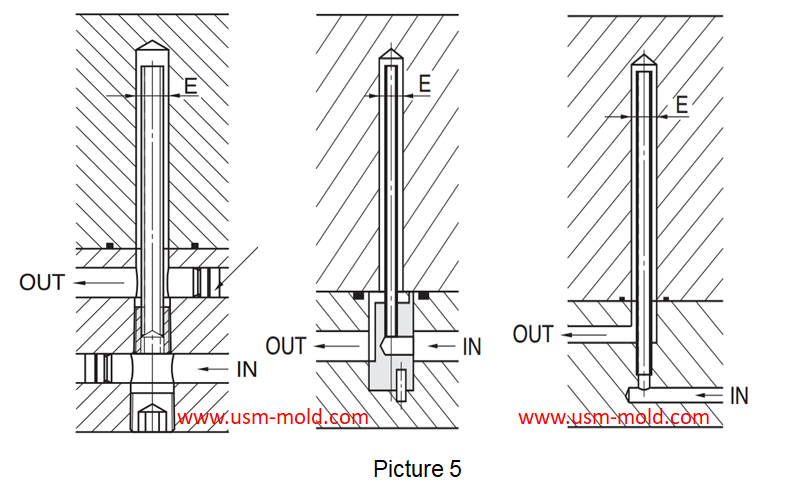

5. Cooling pipe type: the cooling pipe is the same as the baffle board for deep cavity molds, or places where the cooling water channel is difficult to reach but has a large amount of heat accumulation, this kind of cooling water gate needs to use a cooling pipe, it is not as pupular as baffle board in normal design, as shown in picture 5.

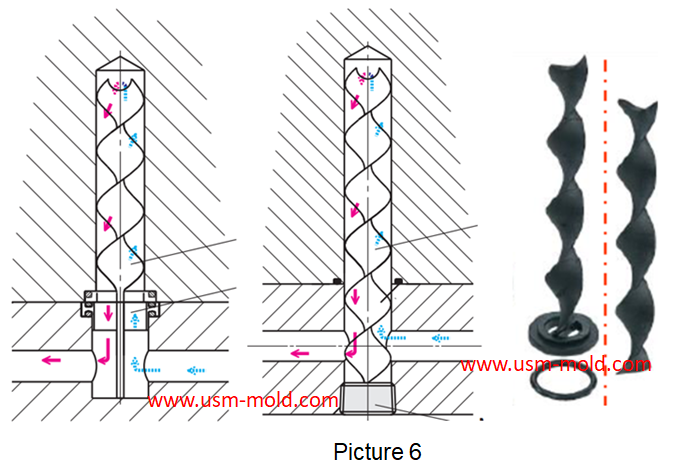

6. Spiaral baffle board: it is normally used as same cooling pipe and baffle board, but the cooling is better, it needs to add spiral pillar or spiral piece, as shown in picture 6.

Pin-point gate of plastic injection mold runner system design

Jan 24, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

Slider angle designing tips

Dec 4, 20231. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...view

The main design points of the design of the plastic mold pouring system

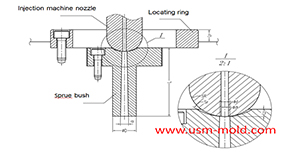

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

Plastic injection mold runner system design

Jan 16, 2022The gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate...view

Insert pin of vengting design for molded parts

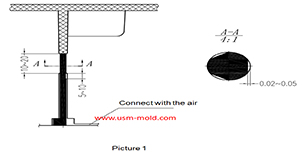

Mar 20, 2022Insert pin of venting: It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end...view

English

English русский

русский