Venting of parting surface

The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from the parting surface is very popular by injection mold factory and injection molding plant. If the parting surface is curved or inclined, CNC machining, electrode processing or wire cutting is generally used, the roughness of the parting surface after processing is relatively high, Ra is generally 1.6~6.3μm, and the exhaust slot is generally processed directly by CNC. If the parting surface is flat, it is usually processed by a grinding. The roughness of the parting surface after the grinding machine is low, Ra is 0.2~0.8 μm, the parting surface is tightly fitted, and the gas in the cavity is not easy to discharge. In this case, an exhaust slot must be opened on the parting surface on one side of the cavity. There are two ways to open the exhaust slot on the parting surface: one is to open the exhaust slot locally, and the other is to open the exhaust slot around the part.

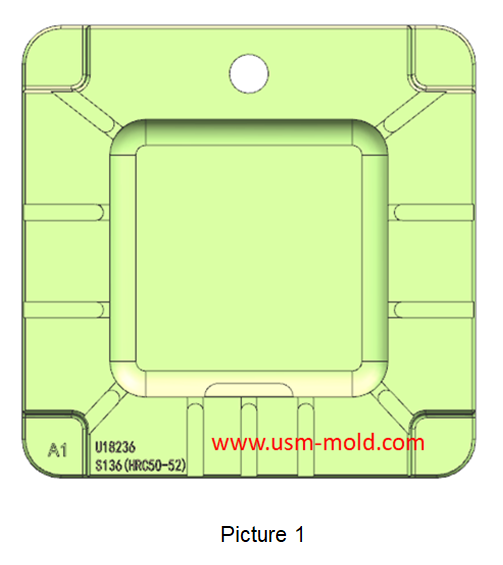

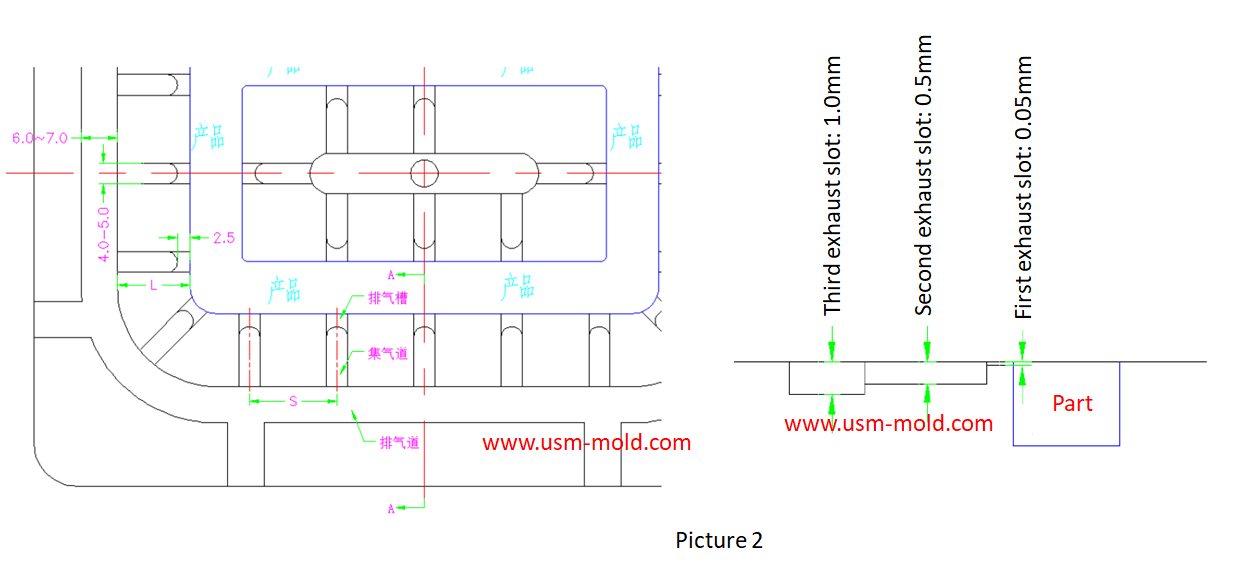

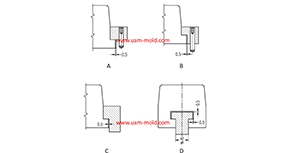

1.Parting surface with partial exhaust slot: this is the most commonly used method of exhaust, the method is to open the exhaust slot where the air is trapped. The position of the exhaust slot is generally combined with the mold flow analysis report based on experience. Determine its final trapped position. This type of venting has less damage to the parting surface of the mold, and it is more flexible and convenient to change the back mold, the specific form is shown in picture 2.

2. Exhaust slot are opened around the parting surface: when the air trap is particularly serious, a large area of exhaust slot can be used to exhaust, as shown in picture 2. If the parting surface of this kind of exhaust slot is flat, it is usually processed with a flat-bottom milling cutter. If the parting surface is curved, it is usually processed with an R-shaped ball cutter, this type of exhaust slot is divided into a first-level exhaust slot, a second-level exhaust slot and a third-level exhaust slot, the depth of which is different.

Vacuum venting mold design for plastic molded parts

Mar 23, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

Slider spring hength and strength calculation

Apr 22, 2024Processing size: 1. ØD2=ØD+2 2. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2) Spring length calculation: (refer to picture 1 for length calculation)...view

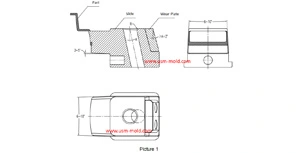

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

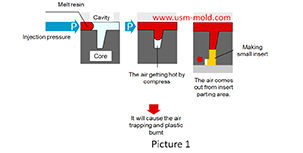

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view

Unique Solutions Mold Profile

Dec 27, 2021USM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square...view

Slider angle designing tips

Dec 4, 20231. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...view

English

English русский

русский