The main reasons for air trapping of plastic injecton mold

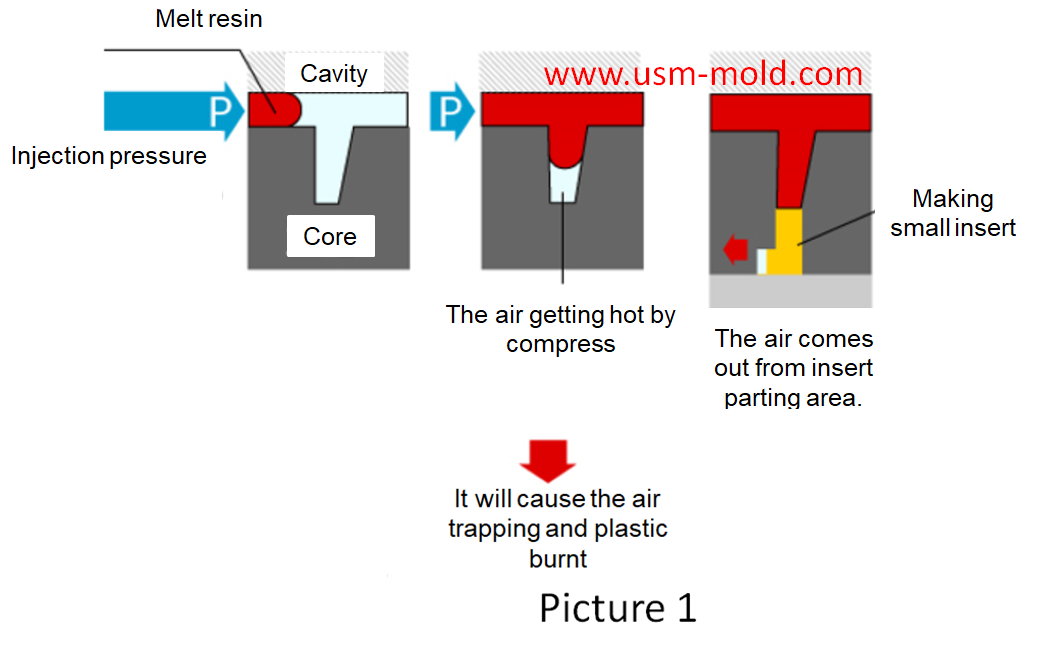

During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized.

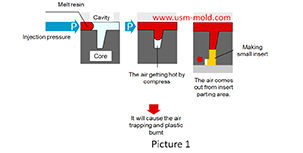

The mechanism of air trapped scorching is that when the air in the mold cavity is extruded by the molten plastic flowing into the cavity, the air will heat due to being compressed if it is in a sealing state without an outlet, and then it leads to combustion and burns.

Since the air is a kind of gas, it can be compressed, but it generates heat when compressed, it is like when we use a pump to inflate our bike tires, the pump gets hot.

The compression of the residual air in the cavity usually occurs in a short time of about 0.1 to 0.5 seconds, because it is compressed under a high pressure of 200 to 500 kgf per square centimeter, it is easy to heat up to the ignition point of the plastic (as shown in picture 1).

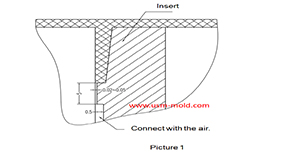

Therefore, for some slight ribs, pillars and other product features in the gas injection mold, it is necessary to make venting slot to let the gas in the mold which can be discharged to the outside of the cavity.

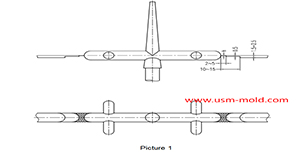

Parting surface venting of runner system

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view

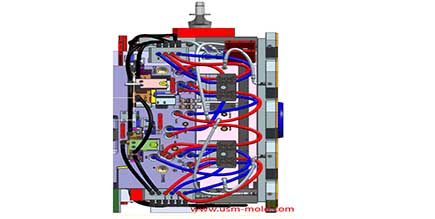

Plastic injection mold cooling system design notice

Feb 14, 2022Design notice of designing the cooling system: 1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer; 2....view

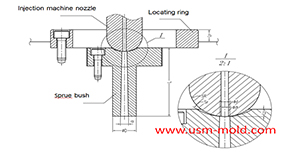

The main design points of the design of the plastic mold pouring system

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view

Venting insert design of molded parts

Mar 13, 2022In the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw...view

Plastic injection mold heating

Feb 16, 2022When the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition,...view

English

English русский

русский