The sub gate of the plastic injection mold runner system

In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among them, the side gate is divided into tab gate, ear protection gate, fan gate, thin gate and so on, the sub gate is divided into sub gate, banana gate, downturning gate and so on.

Picture 1a

According to the production automation, it is divided into manual removal and automatic removal, the side gate and direct gate are need to be manually removed after production,but the sub gate and pin-point gate and valve gate of hot runner are automatic removed.

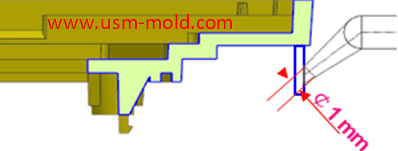

Sub gate: The sub gate is evolved from pin-point gate and has a similar characteristic as pin-point gate, the difference is that the sub gate in one side of parting surface and enters the cavity in an oblique direction. Opening the mold elbow can automatically pull off the gate, and the gate position can be set on the side, end and back of the plastic part, so that there is no gate mark on the outer surface of the plastic part (as shown in picture 1ab), the structure of the same elbow mold can be simplified to a single parting surface structure.

Picture 1b

Advantages:

1. The gate can be cut off automatically, eliminating the need for subsequent processing and realizing automatic production;

2. The gate position selection is big, it can be set freely on the outside or inside of the part;

3. The gate is small, which has little effect on the appearance of the product, and some sub gates are hard to see with the eyes;

4. The mold structure can be simplified, for some products with high appearance requirements, we must make a three-plate mold to realize it if we use the pin-point gate, but it only two-plate mold is needed if changing to sub gate, which reduces the mold structure complexity greatly, it also reduces the mold thickness and save the mold cost.

Disadvantages:

1. Pressure loss too much, it ususall in the range of Ø0.8~2.0mm due to the sub gate is relatively small, a large part of the pressure will be lost when the plastic pass through the small gate;

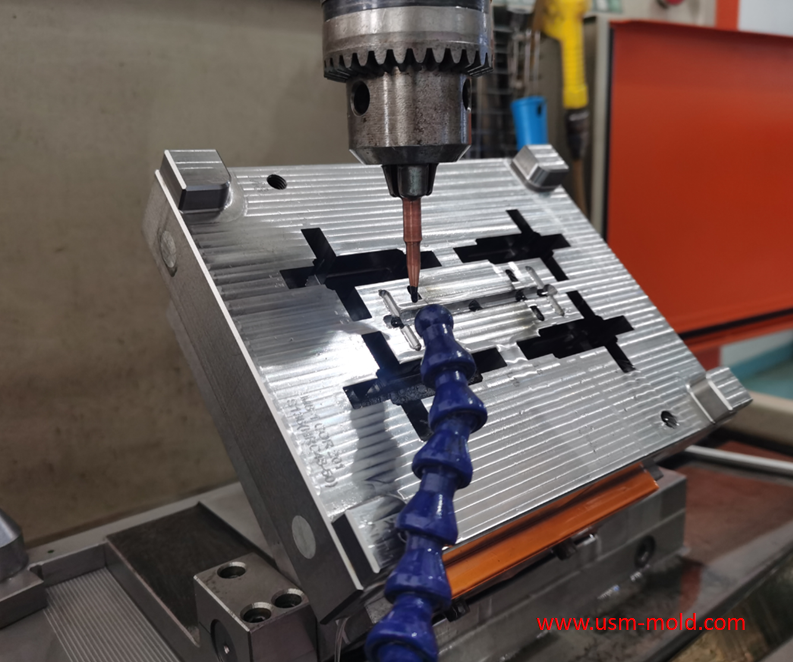

2. The processing is more complicated, this kind of small gate generally needs to place the mold core into a vertical angle to follow the gate, and then use EDM to make process(as shown in picture 2);

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view

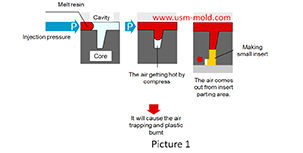

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view

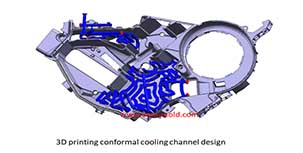

Controling method of plastic injection mold temperature

Feb 15, 2022Except for heat radiation and heat convection from the mold, most of the heat bring into the mold by the plastic needs to be taken out of the mold by the circulating heat transfer medium by heat...view

USM Blogo Opening

Oct 27, 2021Hello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need. USM is a professional plastic injection mold and molding...view

The design requirements of slider wear plate

Jan 2, 20241. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...view

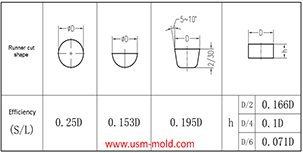

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

English

English русский

русский

_20250310164515A048.webp)