The design requirements of slider wear plate

1. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC;

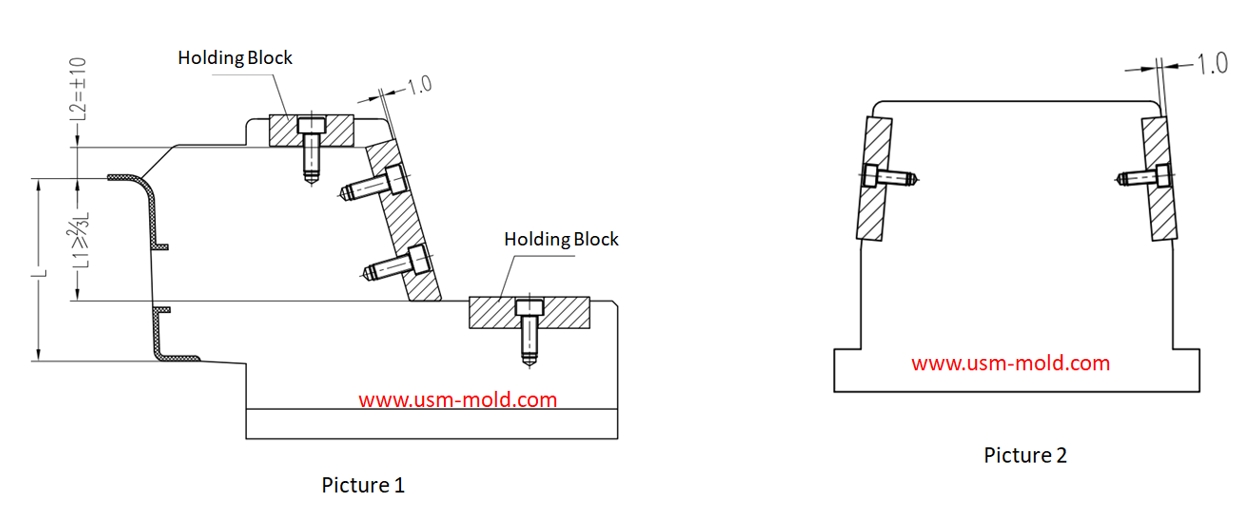

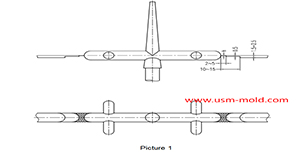

2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);

3. The minimum surface of the back wear plate is required to be more than 2/3 higher than the forming surface (see picture 1 L1≥2/3L);

4. The highest surface of the back wear plate is required to be ±10mm from the highest forming surface (see picture 1);

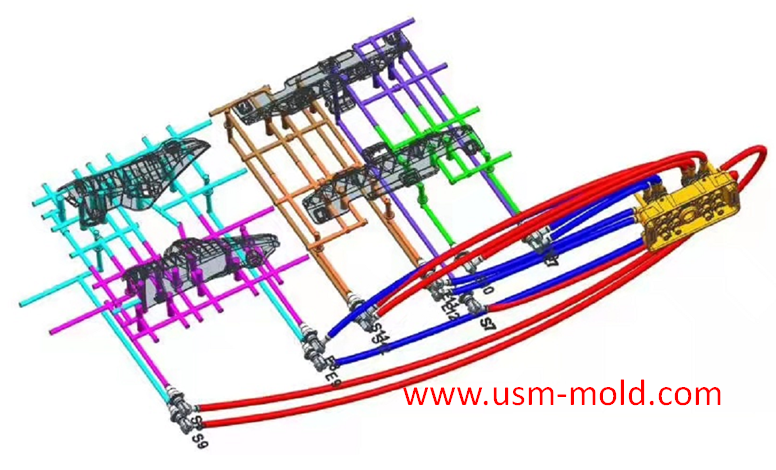

5. If the length and width of the slider are more than 100mm, in order to ensure that the force of the slider is uniform and does not shift after the mold is closed, the top surface of the slider must be designed with necessary parallel blocks (see picture 1);

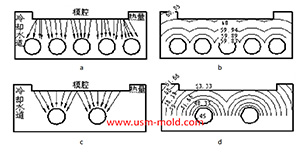

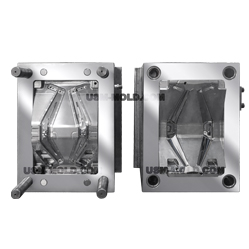

6. When the side of the slider and the core side are inserted with a slope (see picture 2), the contact surface must be inserted with wear plate.

Factors affecting the cooling rate of parts by injection molding

Feb 9, 2022It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature...view

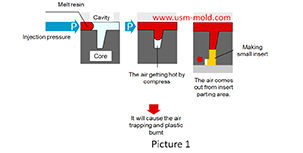

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view

Venting of parting surface

Mar 7, 2022The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...view

Temperature system of injection mold

Feb 8, 2022Hi everyone,the mold cooling time is the longest during injection, so the design of mold temperature system controlling is very important, we will talk about mold cooling, heating system in following...view

What is Ejection Molding?

Dec 28, 2021The process to get injection molded products is called injection molding, or called injection. Injection molding is an important method in polymer molding processing, it is characterized by a short...view

Parting surface venting of runner system

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view

English

English русский

русский

_20250310164515A048.webp)