Main application of gas-assisted molding technology

Gas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the material saving rate of this kind of parts can be reached in 20%-40%. For large flat parts, such as door panels, refrigerator trays, automotive interior and exterior parts, gas-assisted reinforcing ribs can be used to eliminate the warping deformation of the flat parts due to residual stress and improve the strength of the parts. Home appliances are the largest application field of gas-assisted technology., for large-screen color TVs and TV brackets over 64cm, more than 90% of them use gas-assisted molding technology, with the increasing market demand for large-screen color TVs and cars, and the popularization of home computers, gas-assisted molding technology will obtain immeasurable economic benefits in the application of household appliances. From the perspective of the trend of replacing steel with plastic, the automobile, furniture, construction, and instrumentation industries will also compete to use gas-assisted molding technology in order to save materials, improve product quality, and participate in the competition in the international market. The promotion and application of gas-assisted molding technology has pushed the plastics processing industry to a new stage of development.

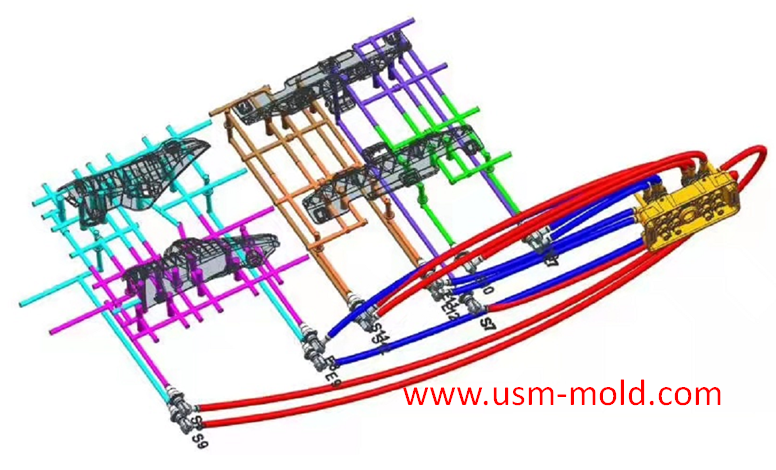

Plastic injection mold runner system design

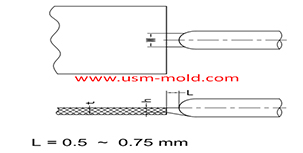

Jan 16, 2022The gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate...view

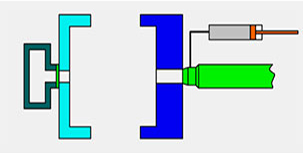

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

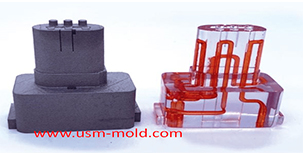

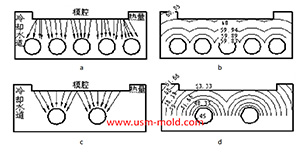

Conformal cooing channel of plastic injection mold

Feb 23, 2022The conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product...view

Temperature system of injection mold

Feb 8, 2022Hi everyone,the mold cooling time is the longest during injection, so the design of mold temperature system controlling is very important, we will talk about mold cooling, heating system in following...view

The common fixing method of angle pin

May 10, 2024The angle pin is a common part of the drive slider, and the fixing and installation methods as following: 1. Pass through the mold plate directly and press the angle pin with the top plate to fix it,...view

Factors affecting the cooling rate of parts by injection molding

Feb 9, 2022It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature...view

English

English русский

русский

_20250310164515A048.webp)