Gas-assisted Injection Molding Equipment

The gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection molding machine is the injection signal connection line. After the injection molding machine transmits an injection signal injection start or screw position to the gas-assisted control unit, it starts a gas injection process, and when the next injection process starts, another injection signal is given, and another cycle starts and so on. The gas used in gas-assisted injection molding must be an inert gas (usually nitrogen), the maximum pressure of the gas is 35MPa, and the maximum pressure of the gas can be up to 70MPa, and the nitrogen purity is ≥98%. The gas-assisted control part is a device that controls the gas injection time and pressure, it has a multi-group gas circuit design that can control the gas-assisted production of multiple injection molding machines at the same time, the gas-assisted control part has a gas recovery function to reduce gas as much as possible consumption.

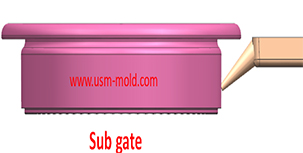

The sub gate of the plastic injection mold runner system

Jan 26, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

The air trapping position in cavity and exhaust method

Mar 2, 2022The air trapping in cavity is usually in the following places: 1. Thin-wall structure cavity, the end of melt flow; 2. The junction of two or more melts; 3. The last area where the melt in the cavity...view

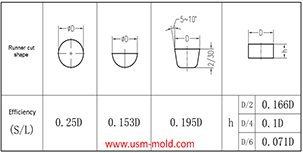

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

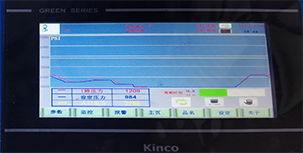

Key points of gas-assisted injection molding process

Apr 20, 2022Gas injection parameters The gas-assisted control part is a device that controls the gas pressure in each stage, the gas-assisted parameters have only two values: gas injection time (seconds) and gas...view

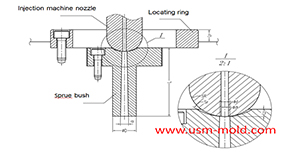

The main design points of the design of the plastic mold pouring system

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

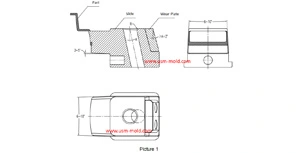

Slider angle designing tips

Dec 4, 20231. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...view

English

English русский

русский