What is Plastic Injection Mold?

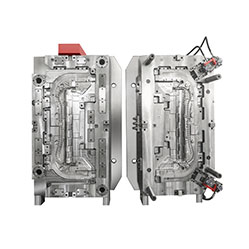

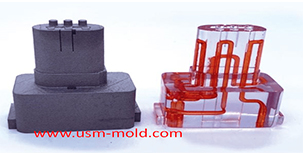

The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and sizes.

The meaning of plastic injection mold:

1. It is suitable for mass production, the mould life is normally in 500-1000K shots, so injection mold is suitable to produce high volume products;

2. The product quality is stable since the mass production mold is made of hardened steel, so the product size and shape are very precise, with suitable injection machines and moulding parameters and production management, the product dimensions will be the same all the time.

3. The molding cycle is short and the production efficiency is very quick, the fastest injection cycle can be achieved within 3 seconds, only the plastic injection mold can meet the production demand if the volume of the products is very large;

4. It has a wide range of adaptability, the mold steel can be chosen according to the different product quantities in order to save mold cost like we normally use 1.1730 and S50C for prototype molds, and the mold life can be reached to 10k shots. But for other large quantities, we will use 1.2343, 1.2344, 1.2738, 718, 718H, 738, 738H, S136, S136H, SKD61,8407, NAK80 and H13 to make different plastic material parts.

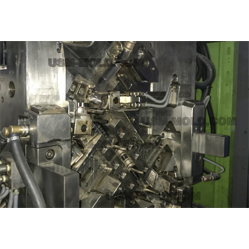

5. It is suitable for automatic production to reduce labour costs and unstable factors.

Injection mold classification:

There are many ways to classify plastic injection mold, according to the plastic material which can be divided into thermoplastic and thermosetting injection molding, we will talk about thermoplastic injection molds as below, and the injection machine can be divided into horizontal injection molding machines and injection molding for vertical injection molding machines, and Greek injection molding machines, etc.

The injection machine can be divided into the following according to different structures:

1. Single parting surface injection mold: it is also called two-plate injection mold which is the simplest injection mold;

2. Double parting surface injection mold: it is also called three-plate injection mold, it has 2 parting surfaces, one parting surface used for picking up the part, the other one used for gating system;

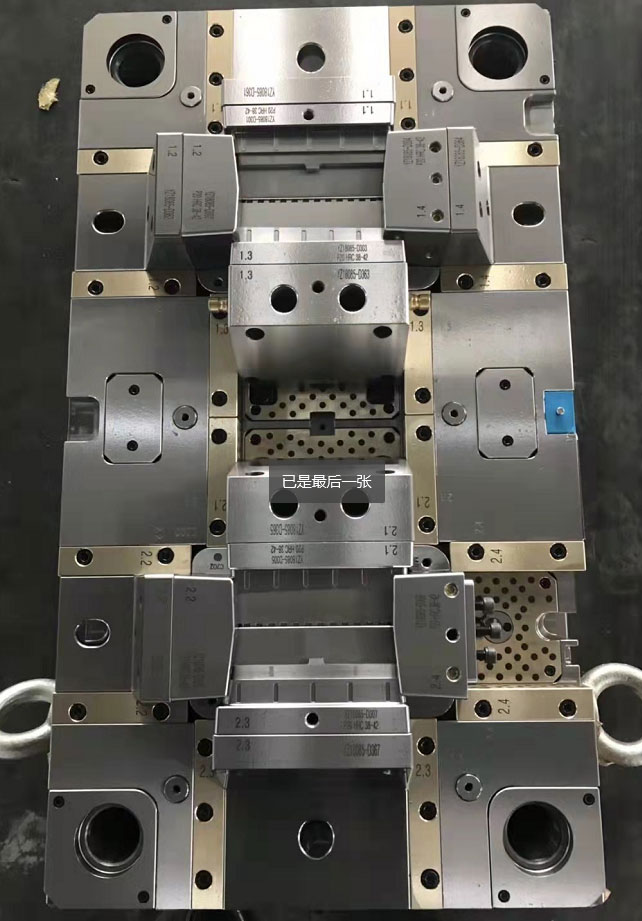

3. With lateral parting screwing injection mold: when the part side contains holes convex or concave structural features, the mold will need to design the side un-screwing (or crosswise) to pick up the plastic part;

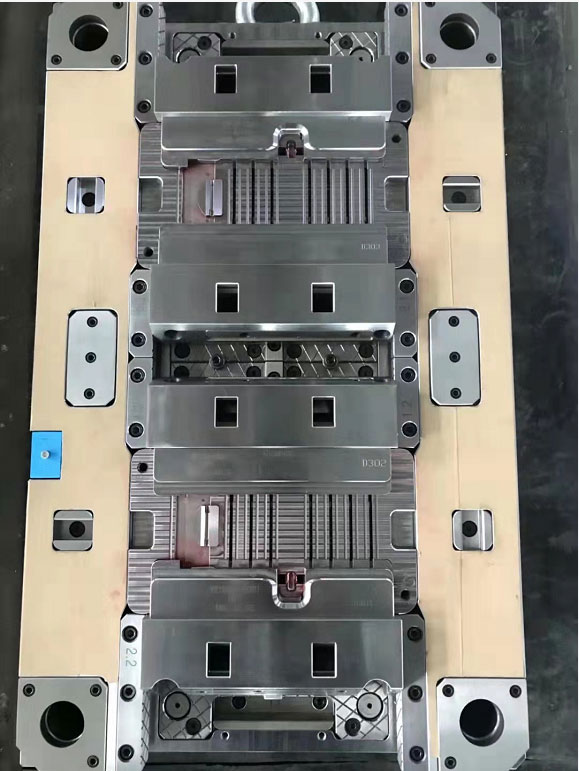

4. Multi-layer injection mold: The mold contains two or more layers of cavities which will be overlapping manner, this type of mold is suitable for small parts, it can increase 80% output comparing the normal mold, but the injection machine requires a larger mold opening stroke, it is also called stack mold;

5. Zero runner injection mold: zero runner injection mold is also called hot runner injection mold, the plastic material will always keep in liquid in the runner by heating so that the pressure is transmitted well and there is no cold runner left after demolding, it can save plastic raw materials and improve production efficiency and product quality.

Vacuum venting mold design for plastic molded parts

Mar 23, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

Gas-assisted injection molding product defects and solutions

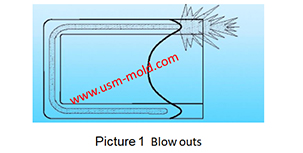

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

Plastic injection mold runner system design

Jan 16, 2022The gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate...view

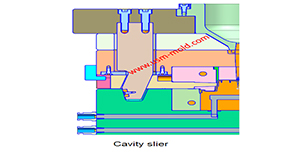

What is the side parting and core pulling mechanisms with their function?

May 31, 2022When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...view

Slider spring hength and strength calculation

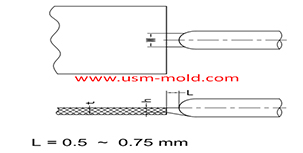

Apr 22, 2024Processing size: 1. ØD2=ØD+2 2. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2) Spring length calculation: (refer to picture 1 for length calculation)...view

Conformal cooing channel of plastic injection mold

Feb 23, 2022The conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product...view

English

English русский

русский