Insert pin of vengting design for molded parts

Insert pin of venting:

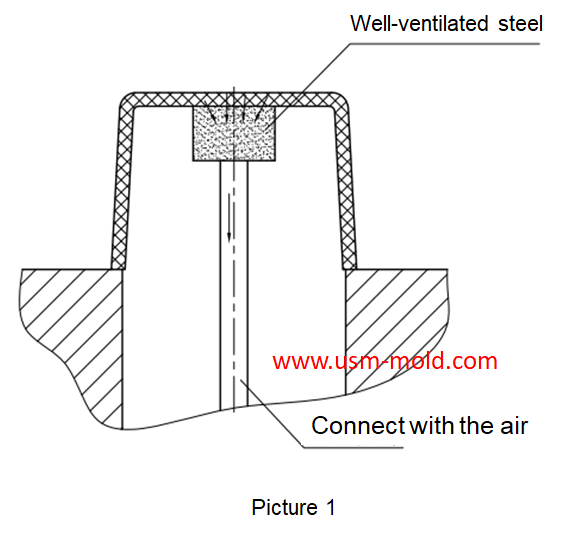

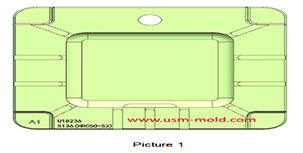

It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end of runner side, and also the exhasut slot will be connected with the air in outside as the venting system, there are some tips for making the insert pin as following:

1. The venting pin should fixed with the mold by H7/g6;

2. There should be an exhaust slot on the side of the venting pin and connect with the air (as shown in picture 1);

3. It will be used venting pin when air trapping position is fixed, but it will be better to use venting insert if the air trapping position is changing in local;

4. The sealing area of insert pin will be made according to the size of insert pin, and the length of sealing is 10-20mm, then it can clearance later;

5. The top of insert pin will make 3 snaps to make venting, and the depth is 0.02~0.05mm;

6. Insert pin is changed by injector pin.

Slider of side core pulling mechanisum assembling

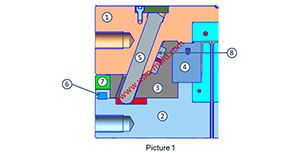

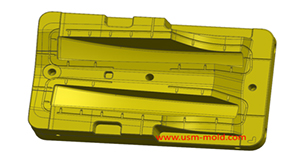

Jul 21, 2022The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism. 1. Lateral forming...view

Venting of parting surface

Mar 7, 2022The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...view

The design principle of the exhaust slot

Mar 6, 2022The exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product...view

Slider spring hength and strength calculation

Apr 22, 2024Processing size: 1. ØD2=ØD+2 2. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2) Spring length calculation: (refer to picture 1 for length calculation)...view

What is Ejection Molding?

Dec 28, 2021The process to get injection molded products is called injection molding, or called injection. Injection molding is an important method in polymer molding processing, it is characterized by a short...view

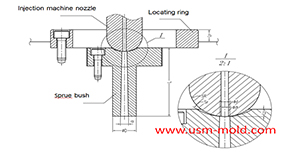

The main design points of the design of the plastic mold pouring system

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

English

English русский

русский