What is Called Draft Angle?

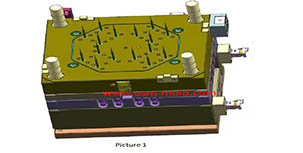

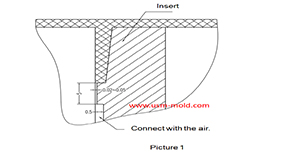

The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in picture 1.

There are 2 common ways to express the draft angle:

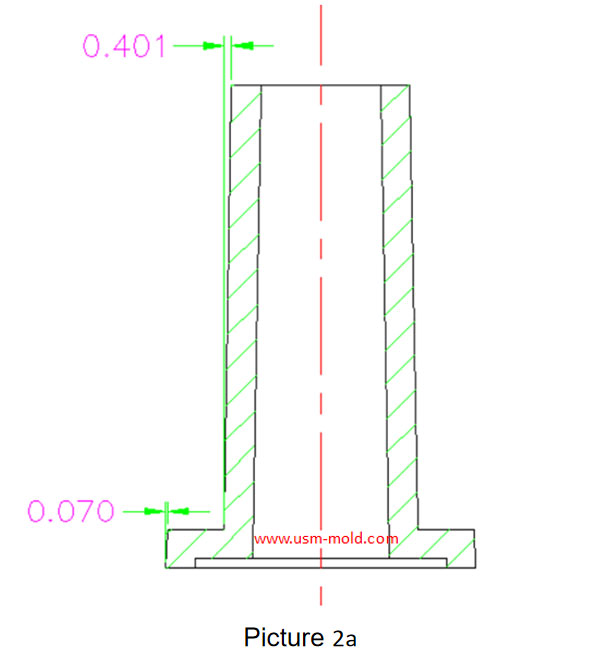

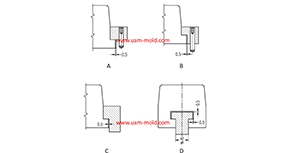

1. To use distance dimension which shows picture 2a, that is the horizontal dimension distance of the draft angle is marked with dimensions, it is normally used for product size higher and strict part dimension, it can help the customer to know the product size directly and clearly;

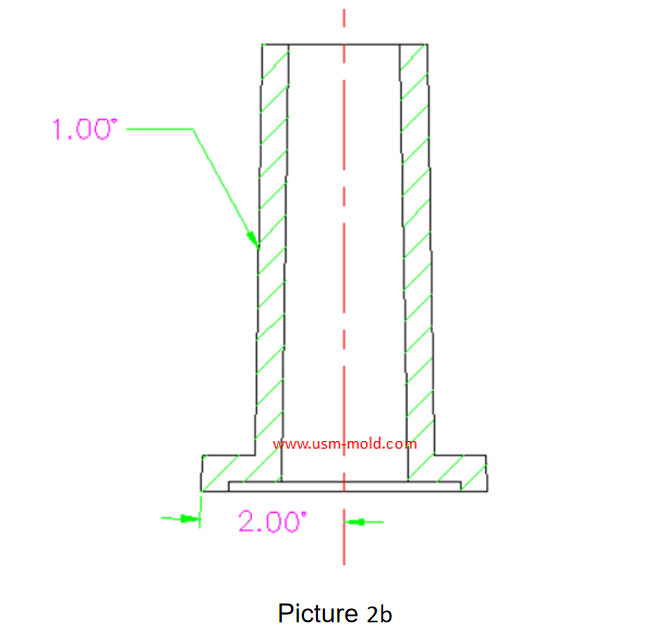

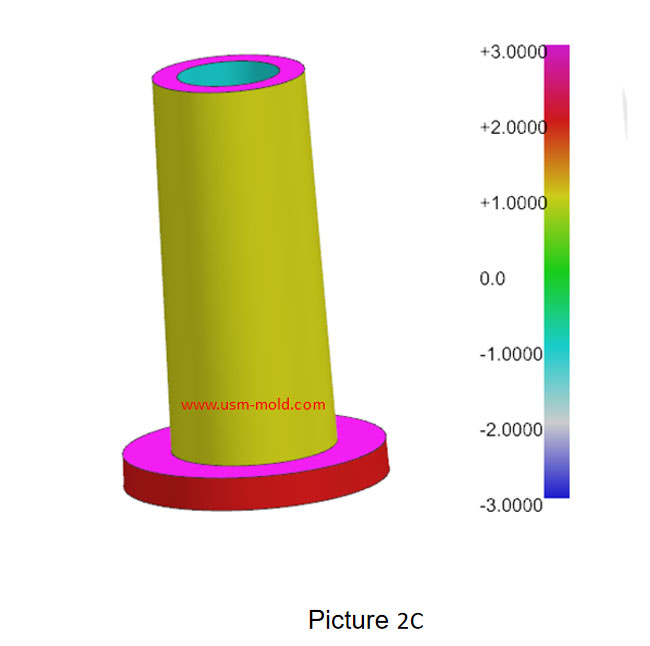

2. To use the angle size which shows picture 2b, that is to remark the draft angle n part surface, and the drat angle will keep the same no matter how long of product size, it is normally used on part surface and ribs, it is the most common way to remark, we also used for analysing the draft angle, but marked in color to express different draft angle which shows in picture 2c.

Factors to determine the draft angle

1. Plastic material type: different plastics will have different strengths and rigidity, and their viscosity will be different, so the draft angle will also be different. The draft angle will be relatively small for rigid PC, PA66+GF30 and other materials, but for weakly rigid PP material, high viscosity POM material, etc., their draft angle is required to be larger;

2. Molding shrinkage: the plastic product has a large tightness to the cavity and core and small adhesion when the shrinkage rate is big, it is necessary to increase the draft angle for the inner surface and reduce the draft angle for the outer surface, but when shrinkage rate is small, the product tightness to the cavity and core is small, and the draft angle is small too;

3. Wall thickness: the tightness is small when the wall thickness is very thin, so the draft angle can be smaller, but the draft angle will be bigger when the thickness is big;

4. Dimension accuracy: the draft angle should be smaller when high dimension accuracy requirements, but for normal dimension accuracy, the draft angle will be bigger;

5. Part surface requirements: The draft angle should be bigger when the part surface is higher, like mirror polishing, the draft angle should be 3 degrees at least, but for texture surface, the draft angle should be made according to the texture number.

What is the effect for the product if not making draft angle?

The part surface will be scratched easily if not making draft angle after demolding, or demolding difficultly.

Who will make the draft angle?

The product designer will design the draft angle when making the part design, but there are some products without any draft angle, USM will do it when making the DFM analysis and give return back to our customers, or assist to design the draft angle if customers needed, and then approved by final customers.

USM specializes in plastic precision injection mold and injection molding with over 16 years of experience, the ability to produce mold at the high international standard, strong engineering and design capability, aggressive lead time and competitive price continues to be the success factor of USM.

Key points of plastic injection mold runner system

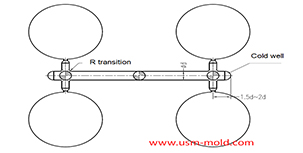

Jan 12, 2022The sub-runner is a transitional channel between the main runner and the gate, as the sub-runner is the longgest part of gating system, so it is very important to enhance the parts quality and improve...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

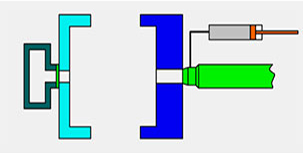

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

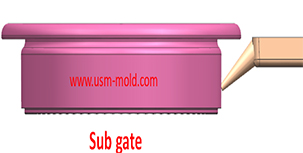

The sub gate of the plastic injection mold runner system

Jan 26, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Venting insert design of molded parts

Mar 13, 2022In the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw...view

English

English русский

русский