Banana gate of plastic injection mold runner system design

In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among them, the side gate is divided into tab gate, ear protection gate, fan gate, thin gate and so on, the sub gate is divided into sub gate, banana gate, downturning gate and so on.

According to the production automation, it is divided into manual removal and automatic removal, the side gate and direct gate need to be manually removed after production, but the sub gate pin-point gate, and valve gate of the hot runner are automatically removed.

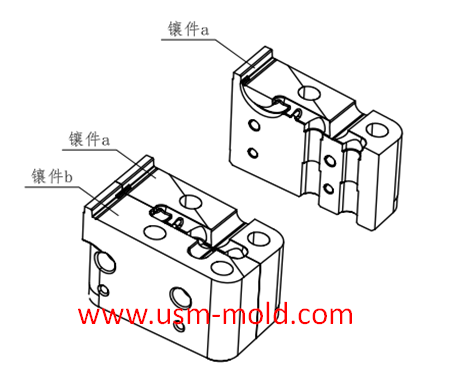

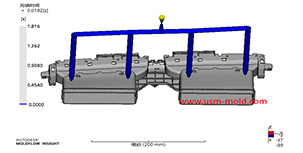

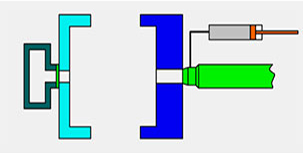

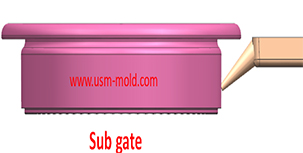

Banana gate: the banana gate is evolved from the sub gate (as shown in picture 1) because it is shaped like the horn of a cow, it is also commonly known as the sub gate, it has a similar hold to the sub gate, the difference is that the processing of the banana gate is more complicated, and it is generally necessary to make a gate insert (as shown in picture 2), the opening of the mold elbow can automatically pull off the gate and the gate position, and also the banana gate can only enter the core, and cannot be made on the side of the product like a sub gate.

Advantage:

1. Made by a professional injection molding supplier, the gate can be cut off automatically, eliminating the secondary processing and realizing automated production;

2. The position of the gate is big, and the position of the gate can be set freely on the outside or inside of the product;

3. The gate is small, which has little effect on the appearance of the product, and some sub-gates are hard to see with eyes;

4. The mold structure can be simplified, for some products with high appearance requirements, if you use the pin-point gate, we must use a three-plate mold to realize it, but we only need to make a two-plate mold if changing to sub gate which can reduce the complexity of the mold structure, but also reduces the mold thickness and saving mold cost.

Disadvantage:

1. Large pressure loss, because the sub gate is generally relatively small, usually in the range of Ø0.8~2.0mm, when the plastic passes through the small gate, a large part of the pressure will be lost;

2. The processing is more complicated, such small gates generally need to make gate inserts;

Plastic injection mold runner system design points

Jan 9, 2022When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...view

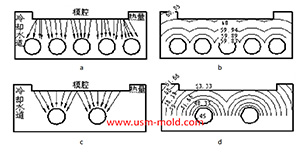

Factors affecting the cooling rate of parts by injection molding

Feb 9, 2022It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature...view

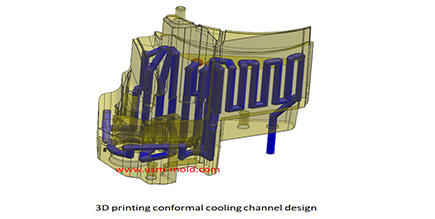

Design principle of plastic injection mold cooling system

Feb 13, 2022Design principle of cooling system In order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in...view

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

The sub gate of the plastic injection mold runner system

Jan 26, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Gas-assisted Injection Molding Equipment

Apr 10, 2022The gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection...view

English

English русский

русский

_20250310164515A048.webp)