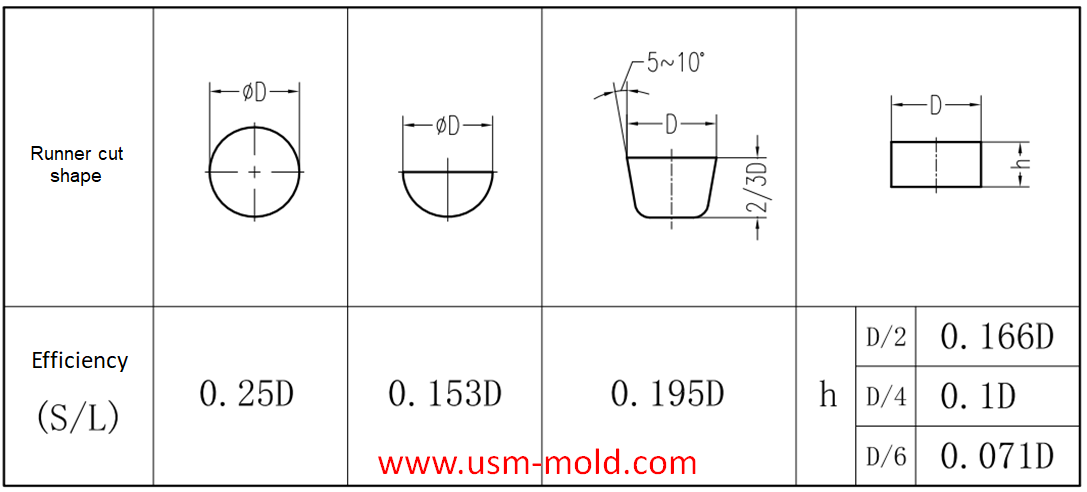

Hydraulic diameter conversion of runners in plastic mold gating system design

Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls, only the average value of the surrounding walls can be calculated.

The main cross-sectional shapes of the shunt: round, trapezoidal and rectangular, in order to reduce the pressure heat loss in the runner, the cross-sectional area of the runner should be maximized, and the internal surface area for heat dissipation should be the smallest.

The efficiency of the runner is expressed by the ratio of the cross-sectional area S of the runner to its cross-sectional circumference L.

Splitter efficiency (hydraulic radius) n=cross-sectional area/cross-sectional circumference=S/L

Hydraulic diameter=4n=4S/L

From the above information, we can see the flow efficiency of different cross-section runners, round and trapezoidal cross-sections are the preferred runners. The size of the runner is usually selected based on the diameter of the circular runner (equal to the hydraulic diameter); when other cross-section flow channels are used, the hydraulic diameter must be converted so that the flow efficiency can meet the calculation requirements (see the example below) ).

Example: It is calculated that a product needs a 8m hydraulic diameter runner, and a semicircular runner is now used; what size of semicircle is more reasonable?

Hydraulic diameter=4n=4S/L=(4*(πr²)/2)/(π*r+2r)=8

Radius r=8*(π+2)/(2π)=6.55

Diameter D=2*r=6.55*2=13.1

Answer: A semicircular runner with a diameter of about 13m is more suitable.

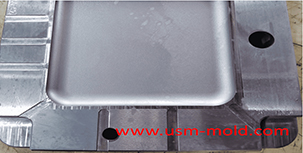

Venting system of plastic injection mold introduction

Feb 27, 2022Hello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

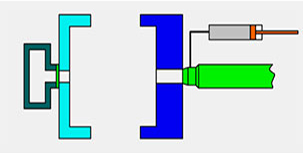

The difference between full shot and short shot of gas-assisted injection molding

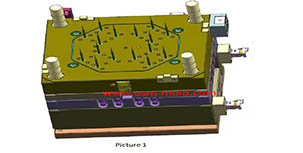

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

The design principle of the exhaust slot

Mar 6, 2022The exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product...view

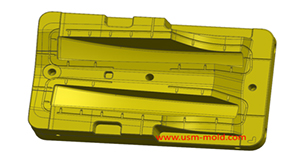

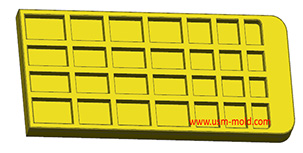

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view_20250317090912A017.jpg)

Several common process of water-assisted injection molding introduction

May 24, 2022According to the design of the injection molding machine and the casting system, the corresponding melt-returning process of water-assisted injection molding can be roughly divided into two types: the...view

English

English русский

русский