USM Blogo Opening

Hello everyone!

Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need.

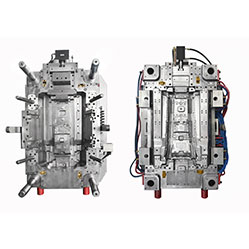

USM is a professional plastic injection mold and molding company that was founded in 2013, it is located in Dongguan city, Guangdong Province, China.

We have been providing service for many different industries, especially for water-assisted and gas-assisted injection mold, overmolding & 2K molding, and pre-deformation mold, we will continue to share more information about the mold.

We are looking forward to contributing to your success!

Welcome to visit our factory and new inquiry.

Popular USM Injection Molds

Related News about USM Injection Mold

The common fixing method of angle pin

May 10, 2024The angle pin is a common part of the drive slider, and the fixing and installation methods as following: 1. Pass through the mold plate directly and press the angle pin with the top plate to fix it,...view_20250317091113A018.jpg)

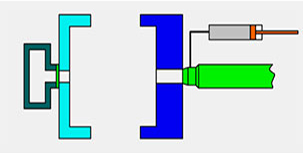

The basic points of designing gas-assisted injection molding

Apr 17, 20221. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel; 2. The gas channel should be arranged in...view

Parting surface venting of runner system

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view

Pin-point gate of plastic injection mold runner system design

Jan 24, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

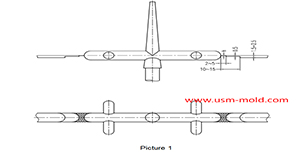

The difference between full shot and short shot of gas-assisted injection molding

Apr 13, 2022Gas-assisted injection molding can be divided into short shot and full shot. Short shot The short shot method is shown in picture 1, it is suitable for thick-walled plastic parts with low mold filling...view

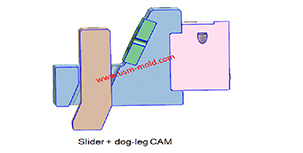

Classification of side parting and core pulling mechanism

Jul 17, 2022According to the structural characteristics of plastic moulding, the side core-pulling mechanisms are divided into the following six categories: 1. The side core-pulling mechanism of "slider + guide...view

English

English русский

русский

_20250310164515A048.webp)