Gas-assisted Injection Molding Equipment

The gas-assisted equipment includes a gas-assisted control part and a nitrogen generator, it is special and seperate system of the injection molding machine, and its only interface with the injection molding machine is the injection signal connection line. After the injection molding machine transmits an injection signal injection start or screw position to the gas-assisted control unit, it starts a gas injection process, and when the next injection process starts, another injection signal is given, and another cycle starts and so on. The gas used in gas-assisted injection molding must be an inert gas (usually nitrogen), the maximum pressure of the gas is 35MPa, and the maximum pressure of the gas can be up to 70MPa, and the nitrogen purity is ≥98%. The gas-assisted control part is a device that controls the gas injection time and pressure, it has a multi-group gas circuit design that can control the gas-assisted production of multiple injection molding machines at the same time, the gas-assisted control part has a gas recovery function to reduce gas as much as possible consumption.

Banana gate of plastic injection mold runner system design

Feb 7, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

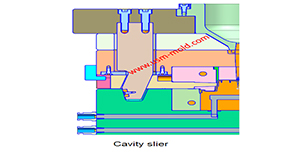

What is the side parting and core pulling mechanisms with their function?

May 31, 2022When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...view

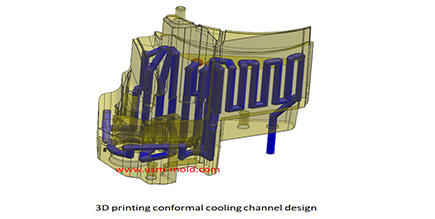

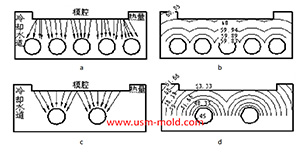

Design principle of plastic injection mold cooling system

Feb 13, 2022Design principle of cooling system In order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in...view

The common fixing method of angle pin

May 10, 2024The angle pin is a common part of the drive slider, and the fixing and installation methods as following: 1. Pass through the mold plate directly and press the angle pin with the top plate to fix it,...view

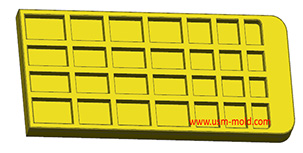

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view

Factors affecting the cooling rate of parts by injection molding

Feb 9, 2022It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature...view

English

English русский

русский