Limitations of gas-assisted injection molding technology

Gas-assisted injection molding technology has obvious advantages in thick wall thickness and pipe parts, but this technology still has many limitations, which are mainly reflected in the following aspects:

.png)

1. Comparing with traditional injection molding, the injection parameters of gas-assisted injection molding are doubled, and the sensitivity of parts to process parameters is improved, therefore, in the molding process, the precise control of various process parameters has a slight error, then the part quality and the stability of the production process will be affected.

2. When the gas channel structure design and mold design of the gas injection mold part are unreasonable, or the operation of the gas-assisted equipment is incorrect, it will cause issues such as poor gas channel and blockage of the needle and so on, it will lead to unstable production or lower productivity.

.png)

3. Gas-assisted injection molding requires a special gas-assisted equipment and molds, use purified nitrogen, or modify the nozzle of the injection machine, or open a gas channell in the mold and add a gas needle to guide the gas into the mold cavity and core, sometimes in the mold pressure and temperature sensors are placed in the cavity to improve control accuracy, so the initial investment cost is relatively high.

4. Higher quality requirements for operators and engineers, traditional injection molding experience cannot solve the process defects of gas-assisted parts, engineers must use CAE software to perform simulation analysis before designing in order to determine a reasonable design plan and various process parameters to reduce repeated mold trial and modification cost.

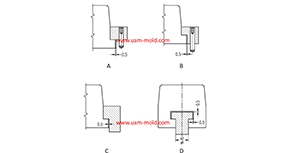

The T slot of slider and guider designing tips

Dec 18, 20231. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable,...view

The design requirements of slider wear plate

Jan 2, 20241. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...view

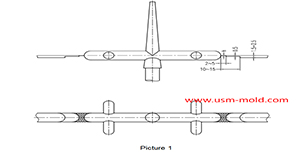

Parting surface venting of runner system

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view_20250317091228A019.jpg)

Main application of gas-assisted molding technology

Apr 7, 2022Gas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the...view

Banana gate of plastic injection mold runner system design

Feb 7, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

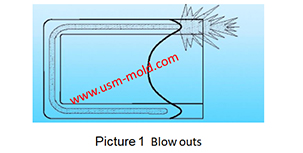

Gas-assisted injection molding product defects and solutions

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

English

English русский

русский

_20250310164515A048.webp)