Different treatment of plastic injection mold cooling system principles

Different treatment principle:

1. The mold temperature is different according to the different plastics, when the plastic requires the molding temperature of the mold to be ≥80°C, the mold must be heated.

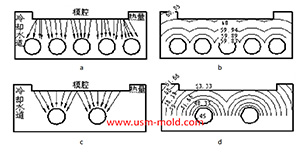

2. The temperature of the cavity should be higher than the temperature of the core, and the temperature difference is generally 20~30℃.

3. For texture cavity with EDM markson the surface, the cavity temperature should be higher than the general polishing surface, when the cavity must be filled with hot water or hot oil, the general temperature difference is about 40 ℃.

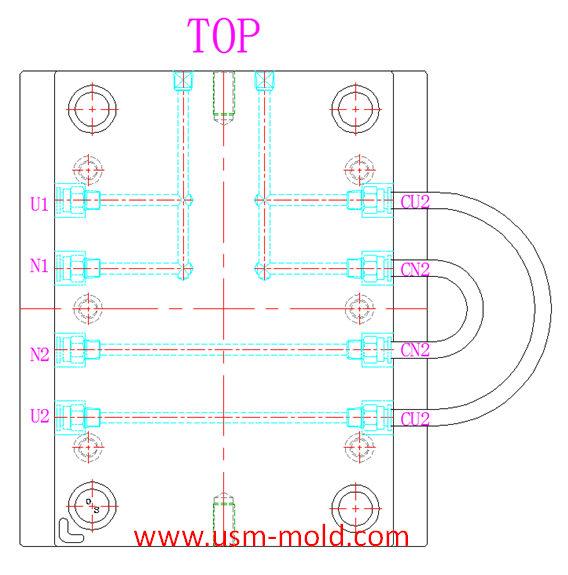

4. For plastic parts with dense meshes, such as speaker shell, the material flow resistance in the mesh area is relatively big and it is difficult to fill. Increasing the mold temperature in this area can improve the filling conditions, the cooling channel in the mesh area is required to be separated from the cooling channel in other areas to flexibly adjust the mold temperature.

5. The mold temperature also depends on the surface quality of the plastic part and the structure of the mold, when designing the temperature control system, it should be targeted from the perspective of the wall thickness of the plastic part, the thick wall should be cooled to prevent shrinkage and deformation; Considering the complexity, cooling should be strengthened at the place where the cavity height fluctuates greatly; the heat of the gate inserts should be strengthened; the cooling channel should be avoided as far as possible through the location of the weld line and the location of the thin wall to prevent the defect more obvious.

6. When the mold temperature is required to be high, such as 70°C or higher, the temperature control of the mold should pay attention to the following:

a. The choice of mold material requires high wear resistance and hardness, heat treatment must be carried out, and the machinability before heat treatment is good.

b. The sealing ring in the mold cooling system should be made of heat-resistant material which is to add the lead.

c. It needs to be a cooling channel between the sliding parts of the mold (such as guide pillar, guide sleeves, etc.) to prevent thermal expansion and contraction from causing movement of moving parts to lock.

d. The shutting-off part of the mold will also strain the shutting-off surface due to thermal expansion and contraction, the shutting-off angle can be appropriately increased to reduce the shutting area, the peripheral interface is formed by inserting.

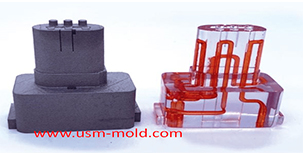

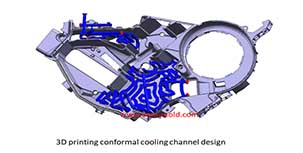

Conformal cooing channel of plastic injection mold

Feb 23, 2022The conformal cooling gate is a new type of mold cooling gate based on 3D printing technolog, because of its processing characteristics, the conformal cooling gate can fit the shape of the product...view

Factors affecting the cooling rate of parts by injection molding

Feb 9, 2022It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature...view

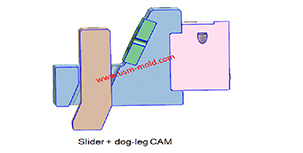

Classification of side parting and core pulling mechanism

Jul 17, 2022According to the structural characteristics of plastic moulding, the side core-pulling mechanisms are divided into the following six categories: 1. The side core-pulling mechanism of "slider + guide...view

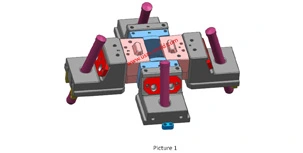

Slider designing tips 2

Nov 22, 20239. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;...view

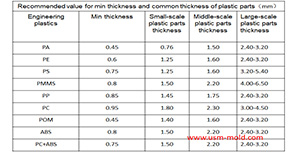

Design principles for wall thickness of plastic products

Jan 3, 2022The principles of wall thickness design for plastic parts are as follows: 1. Making the wall thickness even is the first principle of plastic part design, it can make filling, cooling and shrinking...view

Controling method of plastic injection mold temperature

Feb 15, 2022Except for heat radiation and heat convection from the mold, most of the heat bring into the mold by the plastic needs to be taken out of the mold by the circulating heat transfer medium by heat...view

English

English русский

русский

_20250310164515A048.webp)