What is the side parting and core pulling mechanisms with their function?

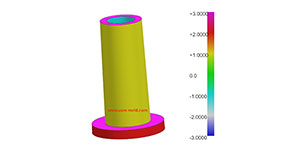

When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot be directly pushed out of the mold by a push mechanism such as a ejector pin. So we will make the movable parts that can move laterally, and then before the plastic parts are demolded and pushed out, the laterally formed parts can be pulled out first, and the plastic parts can be pushed out of the mold, otherwise it cannot be demolded. The entire mechanism that drives the laterally formed parts for lateral splitting and core-pulling and reset is called the lateral splitting and core-pulling mechanism. For the case of forming lateral bosses, it is often called side parting; for forming side holes or undercuts, it is often called side core pulling.

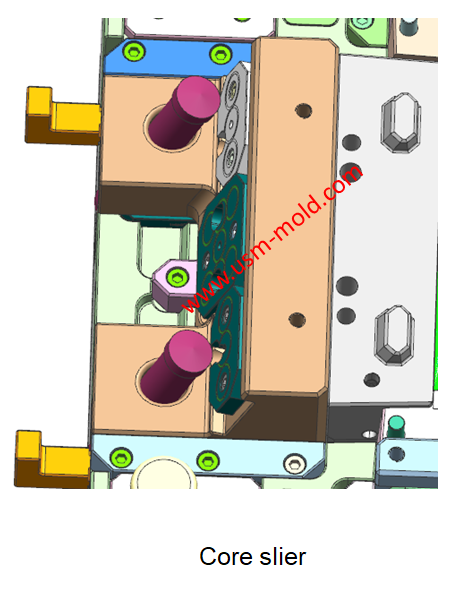

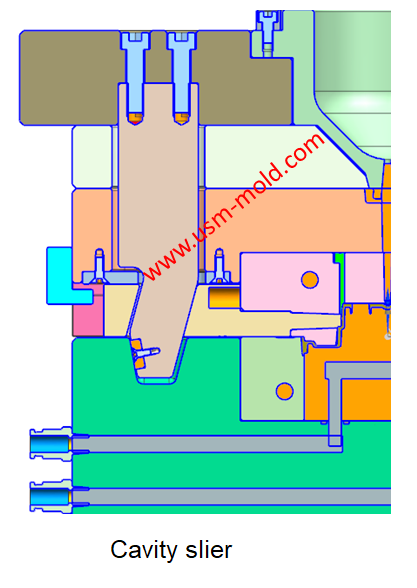

The main function is to get rid of the undercur on the plastic part, so that the plastic part can be smoothly released from the mold. The structures often used in the mold include slider core pulling, lifter core pulling, unscrewing core pulling, etc., and the slider can be subdivided into cavity slider, core slider, inner slider (tunnel slider) and so on.

USM Blogo Opening

Oct 27, 2021Hello everyone! Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need. USM is a professional plastic injection mold and molding...view

What is Called Draft Angle?

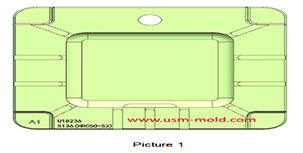

Dec 29, 2021The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in picture 1....view

Venting of parting surface

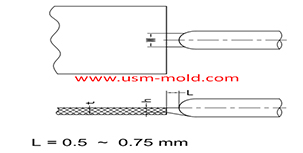

Mar 7, 2022The exhaust slot on the parting surface is easy to clean and processing, also not easy to be blocked, and has a good exhaust effect, it is the main area where the gas is exhausted, so the exhaust from...view

Plastic injection mold runner system design

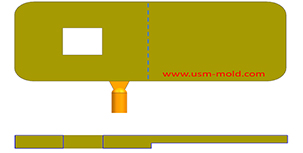

Jan 16, 2022The gate is the connecting part between the runner and the cavity, and is also the end part of the injection mold gating system, the molten plastic enters the cavity and core side through the gate...view

The air trapping position in cavity and exhaust method

Mar 2, 2022The air trapping in cavity is usually in the following places: 1. Thin-wall structure cavity, the end of melt flow; 2. The junction of two or more melts; 3. The last area where the melt in the cavity...view

Gate position determination of plastic injection mold runner design system

Jan 17, 2022In the selection of gate location, the following issues should be paid attention to: 1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt...view

English

English русский

русский