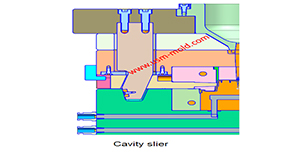

Classification of side parting and core pulling mechanism

According to the structural characteristics of plastic moulding, the side core-pulling mechanisms are divided into the following six categories:

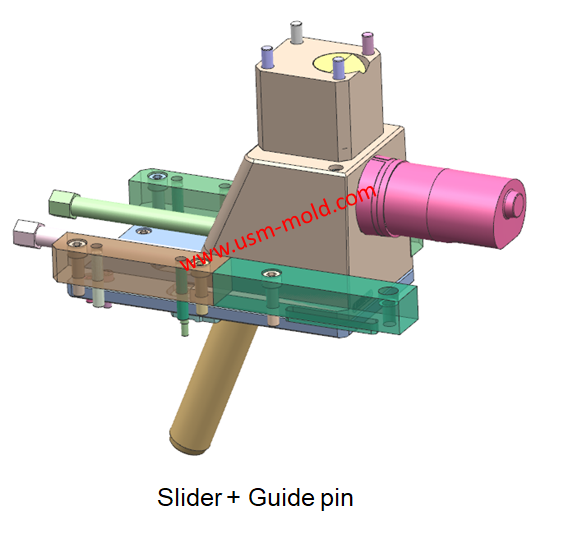

1. The side core-pulling mechanism of "slider + guide pin";

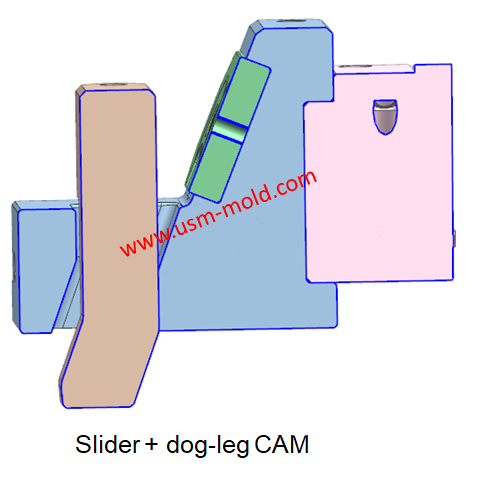

2. The side core-pulling mechanism of "slider +dog-leg CAM";

3. The side core-pulling mechanism of "slider + T-block";

4. The side core-pulling mechanism of slider + hydraulic cylinder;

5. Side core pulling mechanism of lifter;

6. side core pulling mechanism of side slider.

Popular USM Injection Molds

Related News about USM Injection Mold

Slider designing tips 2

Nov 22, 20239. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;...view

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view

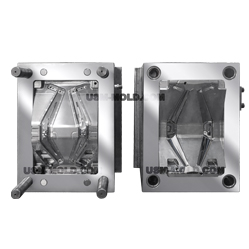

What is the side parting and core pulling mechanisms with their function?

May 31, 2022When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...view_20250317091228A019.jpg)

Main application of gas-assisted molding technology

Apr 7, 2022Gas-assisted molding has a particularly obvious effect on the material saving of tubular and rod-shaped plastic parts, such as car handles, seat armrests, window frames, and wood-like furniture, the...view

The design requirements of slider wear plate

Jan 2, 20241. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...view

Venting system of plastic injection mold introduction

Feb 27, 2022Hello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the...view

English

English русский

русский

_20250310164515A048.webp)