What is Ejection Molding?

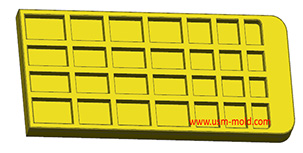

The process to get injection molded products is called injection molding, or called injection. Injection molding is an important method in polymer molding processing, it is characterized by a short molding cycle and high production efficiency, it can produce complex shapes and precise dimensions at one time, it has strong molding adaptability, a wide range of products, and it is easy to realize automatic production, because of its wide range of applications.

The basic process of injection molding: the granular polymer material (hereinafter referred to as plastic material) is heated and extruded by the screw of the injection molding machine to become a molten melt, it enters into the injection barrel, runner and gate to mold cavity and core side, the result of injection molding is to produce plastic parts that meet requirements.

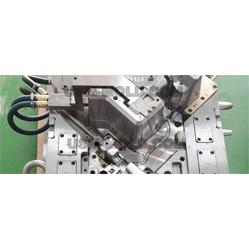

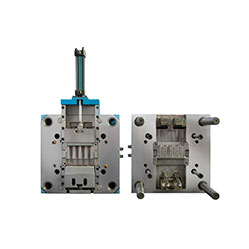

The mold must have a well-designed and well-manufactured mold, advanced equipment and reasonable injection parameter to make qualified products, so people often make as the 3 elements by mold , injection molding machine and injection molding process as the three basic elements for the perfect injection molding process.

As one of the main tools of injection molding, the mold quality, precision, manufacturing time and production efficiency in the injection molding process affects the product quality, output, and product cost directly, and also ultimately determines the company’s reaction speed to market competition.

USM specializes in plastic precision injection mold and injection molding with over 16 years of experience, the ability to produce mold at the high international standard, strong engineering and design capability, aggressive lead time and competitive price continues to be the success factor of USM.

Reasons for making the exhaust system of the injection mold

Feb 28, 2022The gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in...view

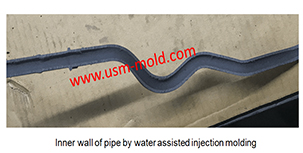

Comparison of water-assisted and gas-assisted injection molding

May 19, 2022Comparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid...view

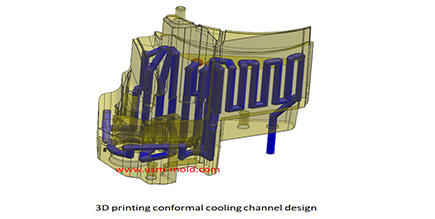

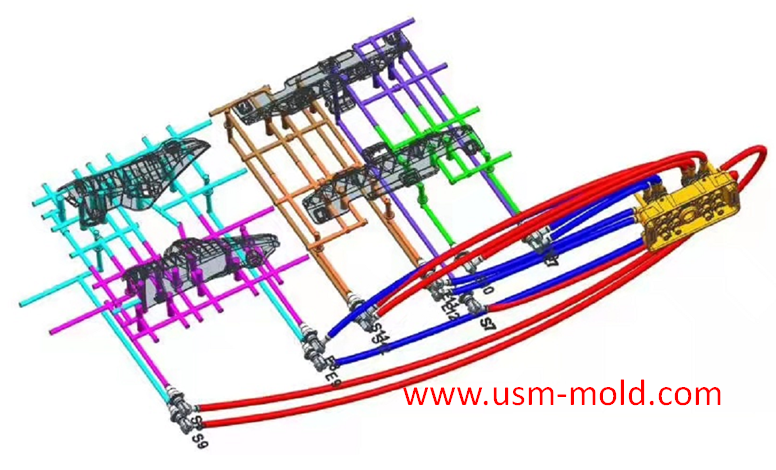

Design principle of plastic injection mold cooling system

Feb 13, 2022Design principle of cooling system In order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in...view

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view

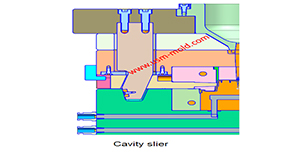

What is the side parting and core pulling mechanisms with their function?

May 31, 2022When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...view

Temperature system of injection mold

Feb 8, 2022Hi everyone,the mold cooling time is the longest during injection, so the design of mold temperature system controlling is very important, we will talk about mold cooling, heating system in following...view

English

English русский

русский