The air trapping position in cavity and exhaust method

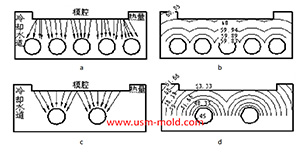

The air trapping in cavity is usually in the following places:

1. Thin-wall structure cavity, the end of melt flow;

2. The junction of two or more melts;

3. The last area where the melt in the cavity reaches;

4. The bottom of the blind hole of the mold cavity is mostly the end of a solid column in the part;

5. Reinforcing ribs of molded parts and the bottom of screw pillars;

6. Dead corners of complex mold cavities.

.png)

Exhaust method in injection mold include as following:

1. Parting surface (including venting slot);

2. The fitting surface of insert;

3. The fitting surface of the push rod or pipe with inner mold insert;

4. Exhaust from side core pulling mechanism;

5. Add a vent needle or insert to vent the air in the trapped area;

6. Breathable steel exhaust;

7. Air valve exhaust;

8. The mold is evacuated and exhausted.

The design principle of the exhaust slot

Mar 6, 2022The exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product...view

Factors affecting the cooling rate of parts by injection molding

Feb 9, 2022It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature...view

Water assisted injection molding introduction

May 11, 2022Like the gas-assisted injection molding process, water-assisted injection molding injects a piece of plastic into the mold cavity and core firstly, and then injects water to squeeze the melt plastic...view_20250317090912A017.jpg)

Several common process of water-assisted injection molding introduction

May 24, 2022According to the design of the injection molding machine and the casting system, the corresponding melt-returning process of water-assisted injection molding can be roughly divided into two types: the...view

Vacuum venting mold design for plastic molded parts

Mar 23, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

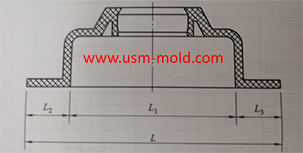

Plastic molding shrinkage rate

Dec 30, 2021Plastic parts getting smaller by shrink, due to the temperature decrease during the molding process, and the shrinkage is expressed by the shrinkage rate, it is common plastic shrinkage rates are...view

English

English русский

русский