What is the side parting and core pulling mechanisms with their function?

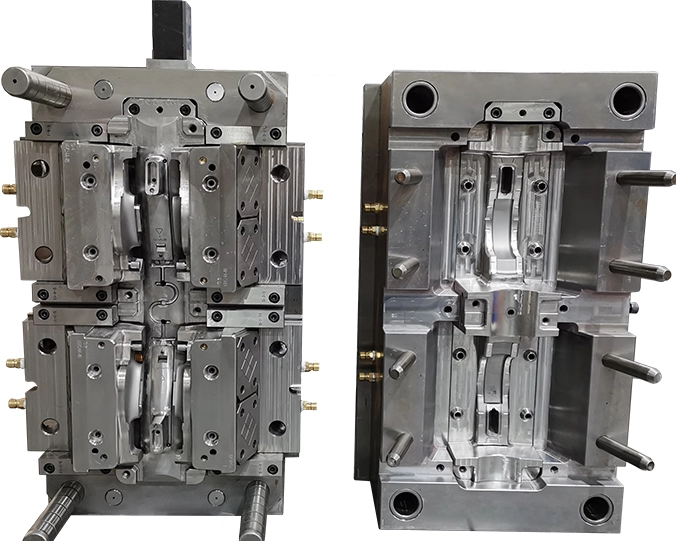

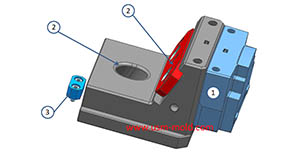

When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot be directly pushed out of the mold by a push mechanism such as a ejector pin. So we will make the movable parts that can move laterally, and then before the plastic parts are demolded and pushed out, the laterally formed parts can be pulled out first, and the plastic parts can be pushed out of the mold, otherwise it cannot be demolded. The entire mechanism that drives the laterally formed parts for lateral splitting and core-pulling and reset is called the lateral splitting and core-pulling mechanism. For the case of forming lateral bosses, it is often called side parting; for forming side holes or undercuts, it is often called side core pulling.

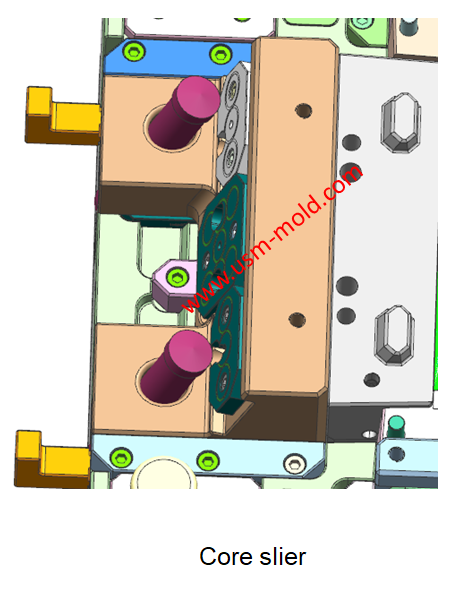

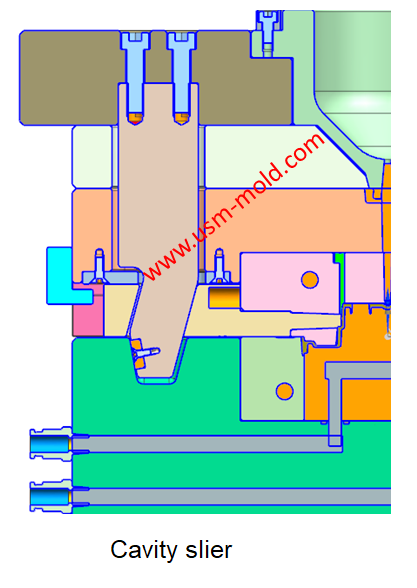

The main function is to get rid of the undercur on the plastic part, so that the plastic part can be smoothly released from the mold. The structures often used in the mold include slider core pulling, lifter core pulling, unscrewing core pulling, etc., and the slider can be subdivided into cavity slider, core slider, inner slider (tunnel slider) and so on.

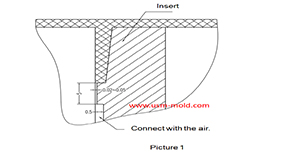

Venting insert design of molded parts

Mar 13, 2022In the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw...view

Unique Solutions Mold Profile

Dec 27, 2021USM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square...view

Slider designing tips 1

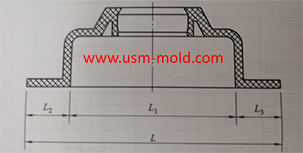

Aug 3, 20221. After the slider core pulls out, the length of staying in the guide pin slot should not be less than 2/3 of the total length of the slider, for special cases, the slider slot can be partially...view

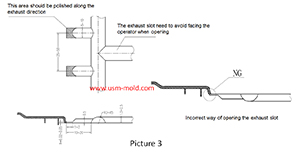

Design standard of exhaust slot

Mar 3, 2022The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...view

Plastic molding shrinkage rate

Dec 30, 2021Plastic parts getting smaller by shrink, due to the temperature decrease during the molding process, and the shrinkage is expressed by the shrinkage rate, it is common plastic shrinkage rates are...view

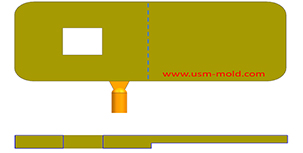

Gate position determination of plastic injection mold runner design system

Jan 17, 2022In the selection of gate location, the following issues should be paid attention to: 1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt...view

English

English русский

русский