USM Blogo Opening

Hello everyone!

Our blog is open today, it is very glad to have the opportunity to meet you here, welcome to visit us whenever you need.

USM is a professional plastic injection mold and molding company that was founded in 2013, it is located in Dongguan city, Guangdong Province, China.

We have been providing service for many different industries, especially for water-assisted and gas-assisted injection mold, overmolding & 2K molding, and pre-deformation mold, we will continue to share more information about the mold.

We are looking forward to contributing to your success!

Welcome to visit our factory and new inquiry.

Popular USM Injection Molds

Related News about USM Injection Mold

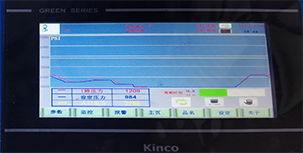

Key points of gas-assisted injection molding process

Apr 20, 2022Gas injection parameters The gas-assisted control part is a device that controls the gas pressure in each stage, the gas-assisted parameters have only two values: gas injection time (seconds) and gas...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

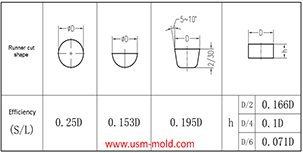

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

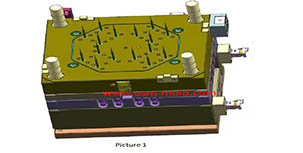

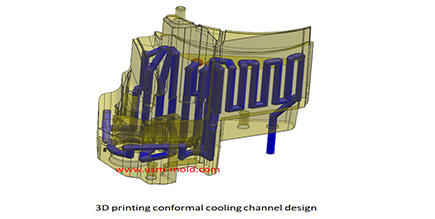

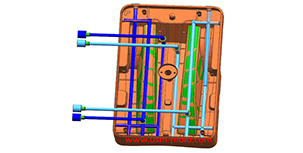

Design principle of plastic injection mold cooling system

Feb 13, 2022Design principle of cooling system In order to improve the efficiency of the cooling system and make the cavity surface temperature distribution even, the following principles should be followed in...view

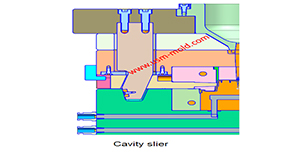

What is the side parting and core pulling mechanisms with their function?

May 31, 2022When there are holes, cavities or cores on the inside or outside of the injection-molded plastic parts that are different from the opening and closing directions of the mold, the plastic parts cannot...view

The principle of mold temperature balance in plastic mold cooling system design

Feb 21, 2022The principle of mold temperature balance: 1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be...view

English

English русский

русский

_20250311083139A052.webp)