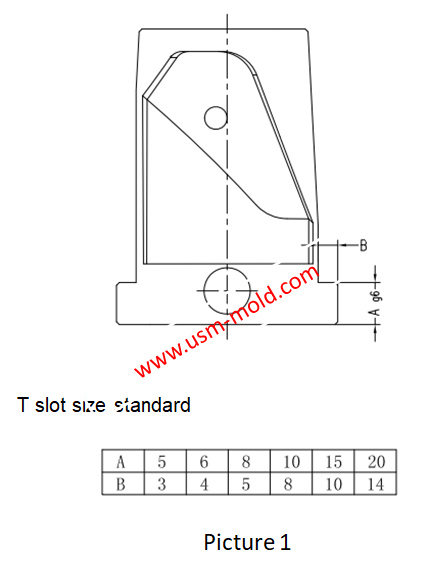

The T slot of slider and guider designing tips

1. The T slot of slot should be designed according to the picture 1, If there is a relatively high slider, the slider T slot is not high enough which will cause the center of gravity to be unstable, so the size A can be made as same as the mold plate after adding the slider holder height;

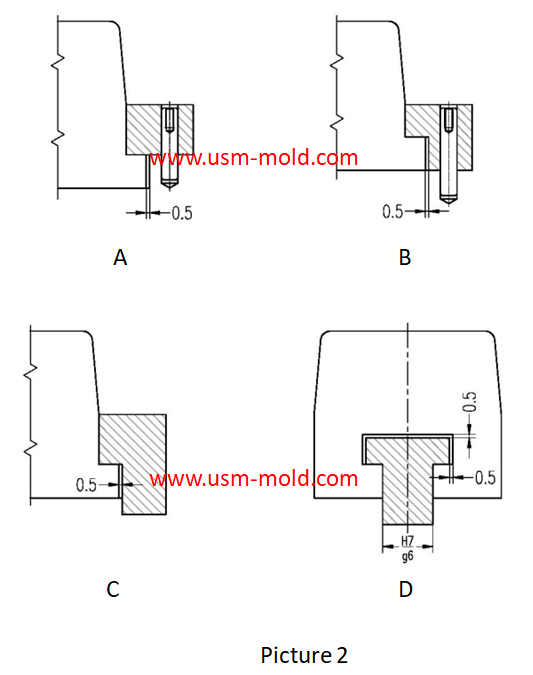

2. There are 4 common types of slider holder which shows in picture 2, it will be better to make the structure of picture 2A;

3 The assembly gap of each slider holder which shows in picture 2;

4. Making at least 2 screws to fix each slider holder, and use 2 dowel pin if there are dowel pins;

5. The friction surface should make oil slot or inserting the graphite between the friction surface of slider holder and slider.

Popular USM Injection Molds

Related News about USM Injection Mold

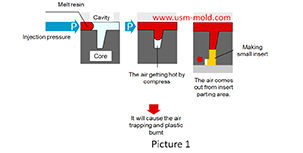

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view

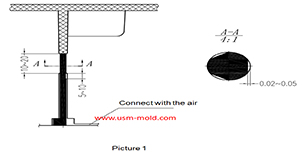

Insert pin of vengting design for molded parts

Mar 20, 2022Insert pin of venting: It is difficult to make exhaust slot when end runner is not in parting surface during injection, and there is no matching gap available, but we could make the venting pin at end...view

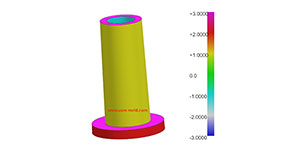

What is Called Draft Angle?

Dec 29, 2021The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in picture 1....view

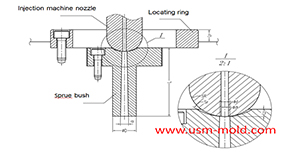

The main design points of the design of the plastic mold pouring system

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

Side gate of plastic injection mold runner system design

Jan 23, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

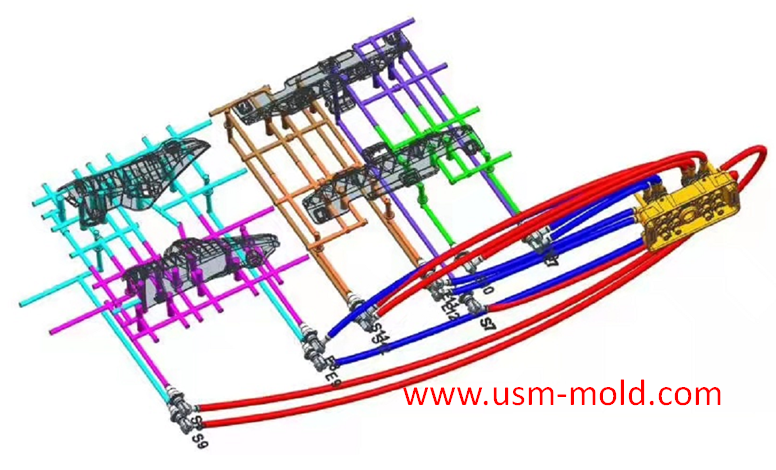

Temperature system of injection mold

Feb 8, 2022Hi everyone,the mold cooling time is the longest during injection, so the design of mold temperature system controlling is very important, we will talk about mold cooling, heating system in following...view

English

English русский

русский