The design requirements of slider wear plate

1. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC;

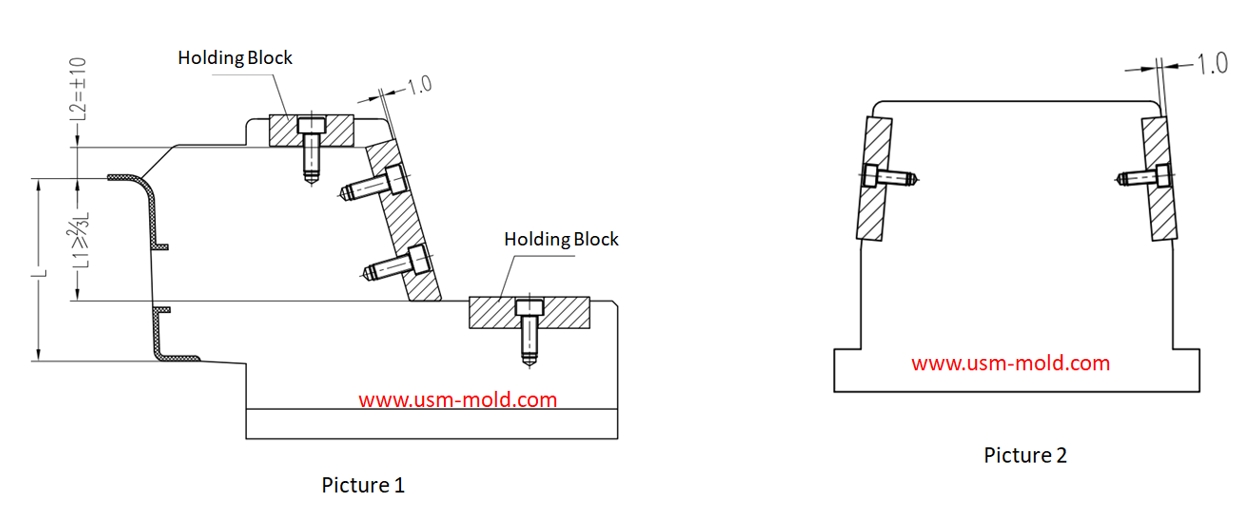

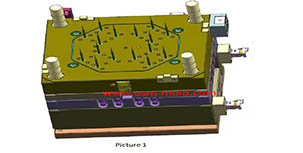

2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);

3. The minimum surface of the back wear plate is required to be more than 2/3 higher than the forming surface (see picture 1 L1≥2/3L);

4. The highest surface of the back wear plate is required to be ±10mm from the highest forming surface (see picture 1);

5. If the length and width of the slider are more than 100mm, in order to ensure that the force of the slider is uniform and does not shift after the mold is closed, the top surface of the slider must be designed with necessary parallel blocks (see picture 1);

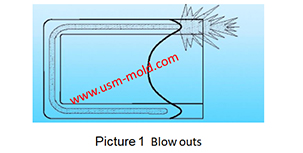

6. When the side of the slider and the core side are inserted with a slope (see picture 2), the contact surface must be inserted with wear plate.

Five Major Steps of the Injection Mold Production Process

Dec 9, 2021Injection mold manufacturing can be roughly divided into the following steps: Process analysis of plastic products. Before the mold design, the designer should fully analyze and study whether the...view

The design requirements of slider wear plate

Jan 2, 20241. The wear plate of slider requires hardening treatment, with a hardness of 45-48HRC; 2. The friction surface of the wear plate is required to be 1.0mm higher than the slider surface (see picture-1);...view

Gas-assisted injection molding product defects and solutions

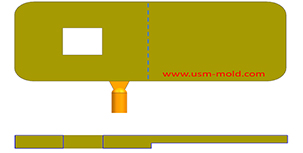

Apr 28, 2022Common defects and solutions of gas-assisted injection moulding: 1. Gas blows out the melt like in picture 1. Reason: insufficient pre-filled amount. When the plastic part is a locally thickened...view

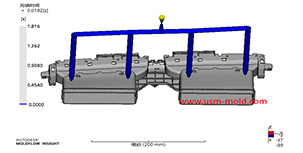

Gate position determination of plastic injection mold runner design system

Jan 17, 2022In the selection of gate location, the following issues should be paid attention to: 1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt...view

Plastic injection mold runner system design points

Jan 9, 2022When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

English

English русский

русский