The design principle of the exhaust slot

The exhaust system of plastic molds is also very important, if the product has air trapping or exhaust system is not suitable will have a big impact on injection molding production and product quality, especially for predeformation mold, the part size will be different if there is air trapping inside mold, which will cause instability during production.

We must follow the following principles when making the mold exhaust slot:

1. The exhaust must be rapid and complete, and the exhaust speed should be compatible with the filling speed;

2. The exhaust slot (hole) should be made in thicker wall thickness of the plastic part;

3. The exhaust slot should be made in parting surface as much as possible, and it is better to make it on the side of the cavity side(according to the shape, characteristics and mold structure of the plastic part, the position of the exhaust slot is allowed to make in core side);

4. The burrs generated by the overflow of the exhaust slot should not hinder the demolding;

5. The exhaust slot should be made as far as possible at the end of the material flow, such as the end of the runner and slug well ;

6. The exhaust direction of the exhaust slot should be toward the reverse operation surface;

7. Refer to the standard data for the depth of the exhaust slot and the depth of the overflow slot, the width and distance, etc.;

8. The exhaust slot should be polished along the exhaust direction;

9. Exhaust slot must be made at the weld mark area;

10. It is better to make the exhaut slot as deep as possible which can not see the flash, but it will be better to see the flash in runner area.

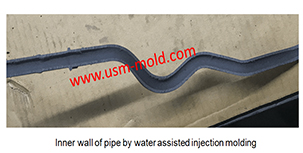

Comparison of water-assisted and gas-assisted injection molding

May 19, 2022Comparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid...view

Plastic injection mold heating

Feb 16, 2022When the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition,...view

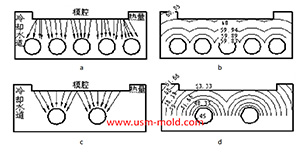

Factors affecting the cooling rate of parts by injection molding

Feb 9, 2022It should be shaped by cooling to get stable plastic part after plastic filling the cavity and core side, so most injection molds need to be equipped with cooling devices to make the mold temperature...view

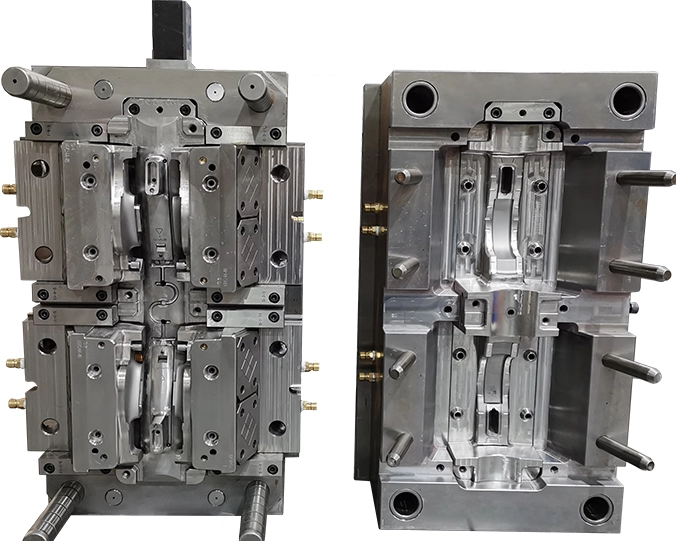

What is Plastic Injection Mold?

Dec 27, 2021The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and...view

Pin-point gate of plastic injection mold runner system design

Jan 24, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

What is Ejection Molding?

Dec 28, 2021The process to get injection molded products is called injection molding, or called injection. Injection molding is an important method in polymer molding processing, it is characterized by a short...view

English

English русский

русский