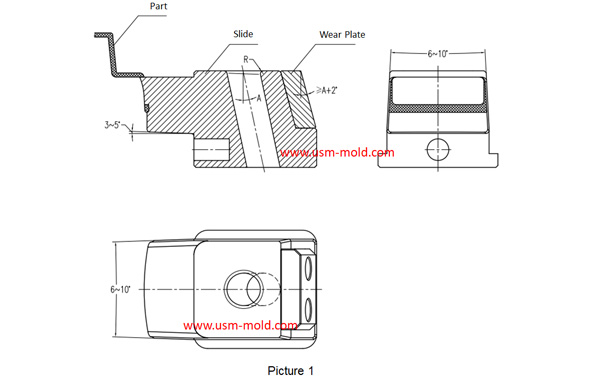

Slider angle designing tips

1. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched;

2. The angle of the locking surface must be bigger than the angle of the angle pin by 2° or more;

3. For the slider driven by the angle pin, the inclination angle of the slider shall not over 30°;

4. The angle (A) of the angle pin shall not over 22°.

Popular USM Injection Molds

Related News about USM Injection Mold

The principle of mold temperature balance in plastic mold cooling system design

Feb 21, 2022The principle of mold temperature balance: 1. Due to the complexity of the plastic parts and mold structure, it is difficult to make the temperature of the mold completely consistent, but should be...view

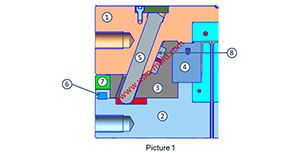

Slider of side core pulling mechanisum assembling

Jul 21, 2022The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism. 1. Lateral forming...view

Slider spring hength and strength calculation

Apr 22, 2024Processing size: 1. ØD2=ØD+2 2. Ll = total spring length (L) - preload value of spring (N) - slider core pulling distance (L2) Spring length calculation: (refer to picture 1 for length calculation)...view

The air trapping position in cavity and exhaust method

Mar 2, 2022The air trapping in cavity is usually in the following places: 1. Thin-wall structure cavity, the end of melt flow; 2. The junction of two or more melts; 3. The last area where the melt in the cavity...view

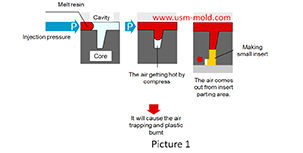

The main reasons for air trapping of plastic injecton mold

Mar 1, 2022During the injection molding process, the front end of the slight ribs may be air trapped and plastic burnt, and also cause the molded part may become black and carbonized. The mechanism of air...view

Plastic part ribs desigining

Jan 4, 2022The ribs function: The role of ribs is to improve the strength and rigidity of the plastic parts, prevent the plastic parts from being distorted and deformed, and will not cause the appearance of the...view

English

English русский

русский