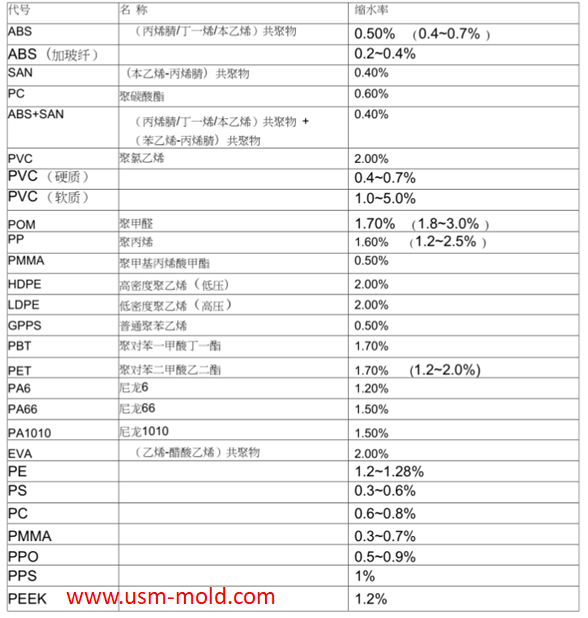

Plastic molding shrinkage rate

Plastic parts getting smaller by shrink, due to the temperature decrease during the molding process, and the shrinkage is expressed by the shrinkage rate, it is common plastic shrinkage rates are shown in picture 1.

Shrinkage calculation: S=(P-L)/S*100%

S: shrinkage rate

P: mold size at room temperature

L: plastic part size at room temperature

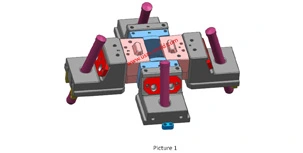

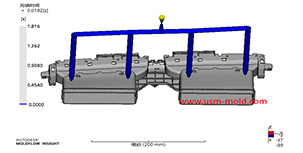

The shrinkage process of plastic parts: the shrinkage of plastic parts is divided into two processes: flow-state shrinkage and solid state shrinkage, and also, the fluid shrinkage is affected by the pressure maintaining and injection machine shrinking which has no effect for parts size. Solid-state shrinkage is divided into two processes: the plastic part shrinkage in cavity and shrinkage after demolding, the shrinkage of plastic parts in the mold cavity is different due to different sizes, now there are three sizes: free shrinkage, hindered shrinkage and mixed shrinkage, as shown in picture 2, the hindered size L1 hardly shrinks in the cavity due to the obstacle of the core, while the free shrinkage size L2, L3 and the mixed shrinkage size L begin to shrink after curing in the cavity, the plastic part shrinks the most within 10 hours after demolding, and is basically stable after 48 hours, but the final stability will take 30 to 60 days, the contraction after 48h is also called post-contraction.

There are many factors to affect the plastic parts dimension accuracy, and the most important and difficult to control is the fluctuation of plastic shrinkage, the main factors that cause fluctuations in plastic shrinkage are as follows:

1. Injection pressure: he greater the pressure in the cavity, the smaller the shrinkage after molding, the shrinkage rates of amorphous plastics and crystalline plastics decrease with the increase of internal pressure in linear and curved shapes respectively.

2. Injection temperature: as the temperature rises, the expansion coefficient of plastic increases, and the shrinkage rate of plastic parts increases, however, as the temperature increases, the density of the melt increases, but the shrinkage rate decreases, the result of the simultaneous action of the two is generally that the shrinkage rate decreases with the increase of temperature.

3. Mold temperature: the general situation is that the higher the mold temperature, the greater the shrinkage of the hindered size L1, the smaller the shrinkage of the free shrinkage sizes L2 and L3, and the mixed shrinkage size L depends on the values of L1 and (L2+L3). , If L1>(L2+L3), the shrinkage rate will decrease with the increase of mold temperature, otherwise it will increase with the increase of mold temperature.

4. Molding time: the longer the pressure-holding time during molding, the more adequate the filling and the smaller the shrinkage rate, the freezing orientation of the plastic increases at same time, the internal stress of the plastic part is also large, and the shrinkage rate also increases, the longer the cooling time of the molding, the more fully the solidification of the plastic and the smaller the shrinkage rate.

5. Geometric structure and wall thickness of plastic parts: severe asymmetry in the structure of plastic parts and uneven wall thickness will cause the shrinkage of various parts of the plastic parts to be inconsistent.

6. The size of the feed inlet: the size of the feed inlet is large, the plastic parts are tight, and the shrinkage is small.

7. Reinforced plastics such as glass fiber: the shrinkage rate decreases with the increase of the filling amount of glass fiber, but the size is stable.

Slider designing tips 2

Nov 22, 20239. The molding parting surface of the slider molding should be made as a shut-off surface as possible, and the width of the shut-off part should be at least 8mm, and do not make a shut-off surface;...view

Plastic injection mold runner system design points

Jan 9, 2022When designing the gating system, Firstly, we should consider making the plastic melt fill the cavity with core side quickly to reduce pressure and heat loss; secondly, it should be economically...view

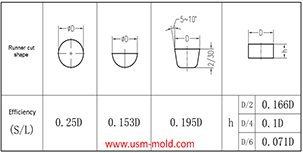

Hydraulic diameter conversion of runners in plastic mold gating system design

Jan 13, 2022Hydraulic diameter refers to 4 times the ratio of the flow cross-sectional area to the perimeter, as the wall shear stress of non-circular pipes is not even distributed along the surrounding walls,...view

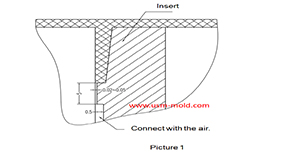

Venting insert design of molded parts

Mar 13, 2022In the thin-walled cavity, the end of the melt flow, the bottom of the blind hole of the mold cavity, the end of the solid column of the plastic part, the bottom of the plastic part rib and screw...view_20250317091113A018.jpg)

The basic points of designing gas-assisted injection molding

Apr 17, 20221. Firstly, considering the suitable wall thickness areas needs to be injected and hollowed out, and then decide how to connect them with the gas channel; 2. The gas channel should be arranged in...view

Plastic injection mold heating

Feb 16, 2022When the plastic injection molding process requires the mold temperature to be above 80°C, a temperature adjustment system with heating function must be provided in the mold. In addition,...view

English

English русский

русский