Plastic cooling factors by injection parameter

1. Plastic parts design: mainly for the wall thickness of plastic products. The thicker thickness of the product, the longer the cooling time. Generally speaking, the cooling time is approximately proportional to the square of the thickness of the plastic product, or proportional to the 1.6th times of the biggest runner diameter, that is the thickness of the plastic product is doubled, and the cooling time is increased by 4 times.

2. Mold materials and cooling methods: mold materials, including mold core, cavity materials, and mold base materials have a big influence on the cooling rate, the higher the thermal conductivity of the mold material, the better the effect of transferring heat from the plastic per unit time, and the shorter the cooling time.

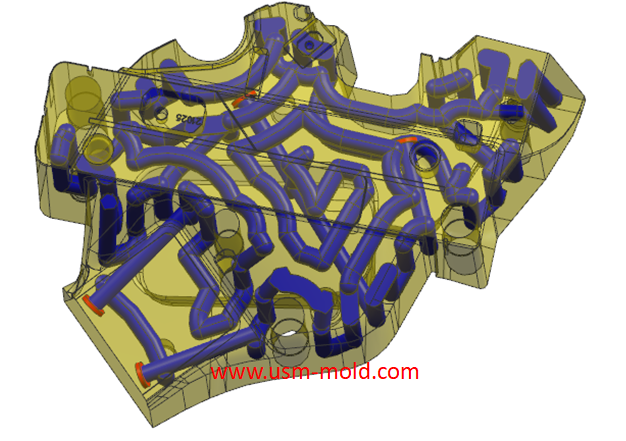

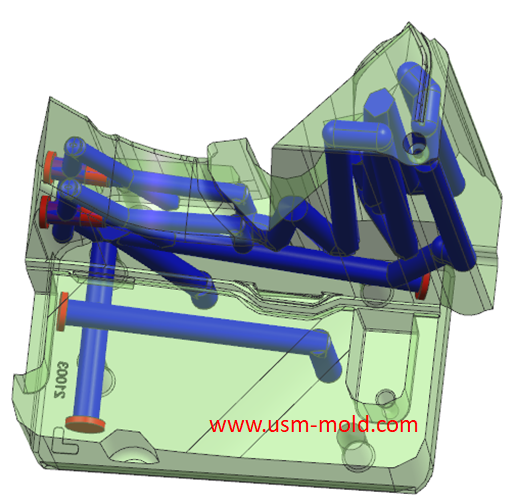

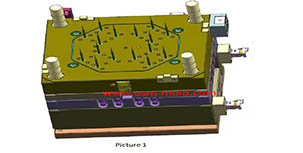

3. Cooling water pipe configuration: the closer the cooling water pipe is to the mold cavity and core, the larger the pipe diameter and the larger the number, the better the cooling effect and the shorter the cooling time.

4. Coolant flow rate: the larger the cooling water flow rate (generally to achieve turbulent flow), the better the effect of cooling water to take away heat by thermal convection.

5. The nature of the coolant: the viscosity and thermal conductivity of the coolant will also affect the heat transfer effect of the mold, the lower the viscosity of the coolant, the higher the thermal conductivity, and the lower the temperature, the better the cooling effect.

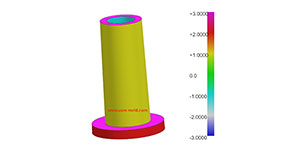

6. Plastic selection: plastic refers to the measurement of the speed at which plastic conducts heat from a hot area to a cold area, the higher the thermal conductivity of the plastic, the better the heat conduction effect, or the lower the specific heat of the plastic, the temperature is prone to change, so the heat is easily dissipated, the heat conduction effect is better, and the required cooling time is shorter.

7. Processing parameter setting: the higher the material temperature, the higher the mold temperature, the lower the ejection temperature, and the longer the required cooling time.

8. The designed cooling gate should ensure the cooling effect is even and fast , the purpose of designing the cooling system is to maintain proper and efficient cooling of the mold, cooling holes should use standard sizes to facilitate processing and assembly.

9. When designing the cooling system, the mold designer must determine the following design parameters based on the wall thickness and volume of the plastic part-the location and size of the cooling hole, the length of the hole, the type of hole, the configuration and connection of the hole, and the flow of cooling liquid speed and heat transfer properties.

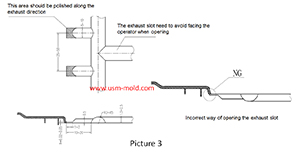

Design standard of exhaust slot

Mar 3, 2022The exhaust system should ensure that the gas in the cavity is smoothly discharged, and also prevent the material from entering and exhausting channels from causing flashing of the product or blockage...view

Direct gate of plastic injection mold runner system design

Jan 19, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

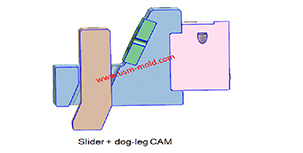

Classification of side parting and core pulling mechanism

Jul 17, 2022According to the structural characteristics of plastic moulding, the side core-pulling mechanisms are divided into the following six categories: 1. The side core-pulling mechanism of "slider + guide...view

Slider angle designing tips

Dec 4, 20231. Normally, all the insertion slopes of the slider are not allowed to be less than 3° to prevent excessive self-locking force and scratched; 2. The angle of the locking surface must be bigger than...view

Design Tips of Vacuum Venting Mold

Mar 30, 2022There are some regular venting way which are parting surface venting, insert venting, insert pin venting and well-ventilated steel, but there is a special way is vacumm venting, it will need vacumm...view

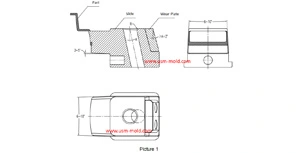

What is Called Draft Angle?

Dec 29, 2021The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in picture 1....view

English

English русский

русский