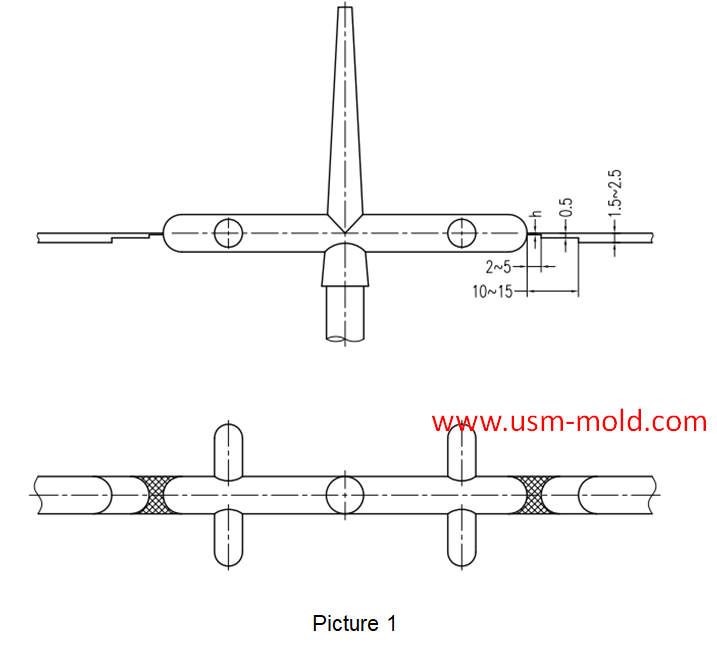

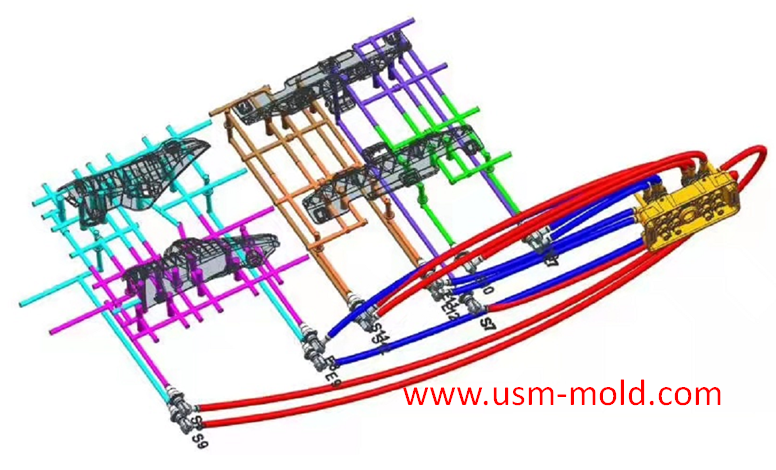

Parting surface venting of runner system

There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting surface, rest of gas will enter the cavity with plastic melt together, but it is better to have less gas inside cavity to reduce the venting cavity.

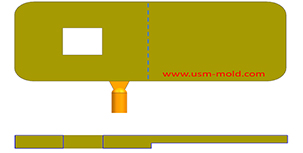

The gas in therunner system should be mainly discharged through the parting surface, the exhaust slot of the gating system is mainly opened at the end of the runner, as shown in picture 1.

The exhaust slot design of the runner:

The depth of the exhaust slot (h) is as deep as the flash edge at the end of the runner;

1. Plastic with good fluidity, h≈0.075mm;

2. Plastic with poor fluidity, h≈0.125m;

The width of the exhaust slot is the same as that of the runner, and the entrance should be polished;

The injection pressure at the runner is high, and the exhaust slot should not be facing the operator.

Plastic molding shrinkage rate

Dec 30, 2021Plastic parts getting smaller by shrink, due to the temperature decrease during the molding process, and the shrinkage is expressed by the shrinkage rate, it is common plastic shrinkage rates are...view

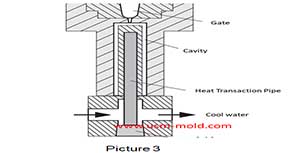

Plastic injection mold common cooling gate

Feb 17, 20221. Straight-through cooling water gate: the straight-through cooling gate is the most commonly used gate for plastic injection mold, and it is also the most convenient type of cooling for processing....view

Temperature system of injection mold

Feb 8, 2022Hi everyone,the mold cooling time is the longest during injection, so the design of mold temperature system controlling is very important, we will talk about mold cooling, heating system in following...view

Gate position determination of plastic injection mold runner design system

Jan 17, 2022In the selection of gate location, the following issues should be paid attention to: 1. The gate position should be set at the maximum wall thickness of the plastic part, so that the plastic melt...view

Unique Solutions Mold Profile

Dec 27, 2021USM (UNIQUE SOLUTIONS MOLD LIMITED) was founded in 2012 and is located in Dongguan City, Guangdong Province, a famous mold manufacturing province in China, the plant covers an area of 3500 square...view

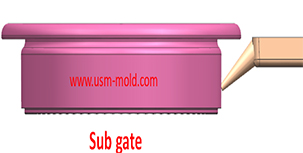

The sub gate of the plastic injection mold runner system

Jan 26, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

English

English русский

русский