Limitations of gas-assisted injection molding technology

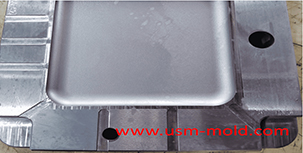

Gas-assisted injection molding technology has obvious advantages in thick wall thickness and pipe parts, but this technology still has many limitations, which are mainly reflected in the following aspects:

.png)

1. Comparing with traditional injection molding, the injection parameters of gas-assisted injection molding are doubled, and the sensitivity of parts to process parameters is improved, therefore, in the molding process, the precise control of various process parameters has a slight error, then the part quality and the stability of the production process will be affected.

2. When the gas channel structure design and mold design of the gas injection mold part are unreasonable, or the operation of the gas-assisted equipment is incorrect, it will cause issues such as poor gas channel and blockage of the needle and so on, it will lead to unstable production or lower productivity.

.png)

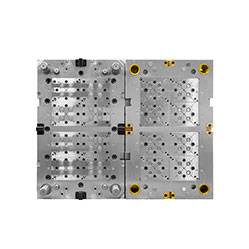

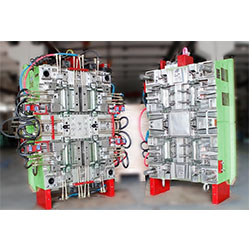

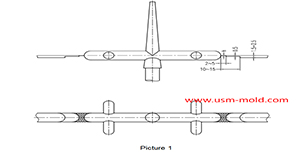

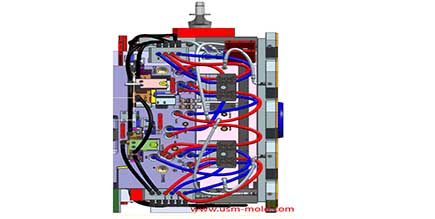

3. Gas-assisted injection molding requires a special gas-assisted equipment and molds, use purified nitrogen, or modify the nozzle of the injection machine, or open a gas channell in the mold and add a gas needle to guide the gas into the mold cavity and core, sometimes in the mold pressure and temperature sensors are placed in the cavity to improve control accuracy, so the initial investment cost is relatively high.

4. Higher quality requirements for operators and engineers, traditional injection molding experience cannot solve the process defects of gas-assisted parts, engineers must use CAE software to perform simulation analysis before designing in order to determine a reasonable design plan and various process parameters to reduce repeated mold trial and modification cost.

Parting surface venting of runner system

Mar 10, 2022There are a large amount of gas in the main and sub channel, these gas are discharged through the pull rod (push rod) during injection processing, a part of gas come out from exhaust slot on parting...view

Venting system of plastic injection mold introduction

Feb 27, 2022Hello everyone, thanks for attention. We’ve discussed about the temperature control system earlier, now we are going to talk about the mold venting information in following 11 articles, from the...view

Plastic injection mold cooling system design notice

Feb 14, 2022Design notice of designing the cooling system: 1. Normal molds can be quickly cooled to obtain a shorter molding cycle, and precision molds can be slowly cooled with a mold temperature thermometer; 2....view

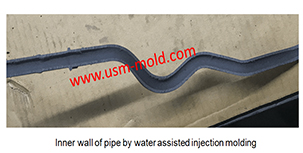

Comparison of water-assisted and gas-assisted injection molding

May 19, 2022Comparing with water-assisted injection molding technology and gas-assisted injection molding technology, the fundamental difference is the nature of the auxiliary molding media used. One is liquid...view

What is Plastic Injection Mold?

Dec 27, 2021The plastic mold is used for injection molding, it is assembled with cavity, core and side slider together, with ejection system and adjustments to produce plastic products by different shapes and...view

Reasons for making the exhaust system of the injection mold

Feb 28, 2022The gas in the injection mold includes not only the air in the cavity, but also the air in the gate and the decomposition gas generated by the plastic melt, and the steam which caused by plastic in...view

English

English русский

русский