Controling method of plastic injection mold temperature

Except for heat radiation and heat convection from the mold, most of the heat bring into the mold by the plastic needs to be taken out of the mold by the circulating heat transfer medium by heat conduction. Heat transfer media include water, oil and beryllium copper, etc, sometimes aluminum alloys are also used.

The mold temperature is generally controlled by adjusting the temperature of the heat transfer medium and adding heat insulation boards and heating rods.

Lower mold temperature is generally achieved by passing warm water (about 25°C) to cavity and "frozen water" (about 4°C) to core, when the gate of the heat transfer medium, that is the cooling water gate cannot pass through certain parts, materials with higher heat transfer efficiency (such as beryllium copper, etc.) should be used to transfer the heat to the heat transfer medium.

To increase the mold temperature, it is generally achieved by passing hot water and oil into the cooling water gate, when the mold temperature is high, we can use an electric heating rod to heat it, for molds that need to be heated, in order to prevent heat loss due to heat conduction, a resin insulation board should be added to the mold panel.

In the hot runner mold, the temperature of the runner plate is required to be high, and it must be heated by a heating rod. In order to avoid the heat of the runner plate from being transferred to the cavity, which causes difficulty in cooling the cavity, the contact surface with the cavity should be minimized during design and use heat insulation sheet to insulate.

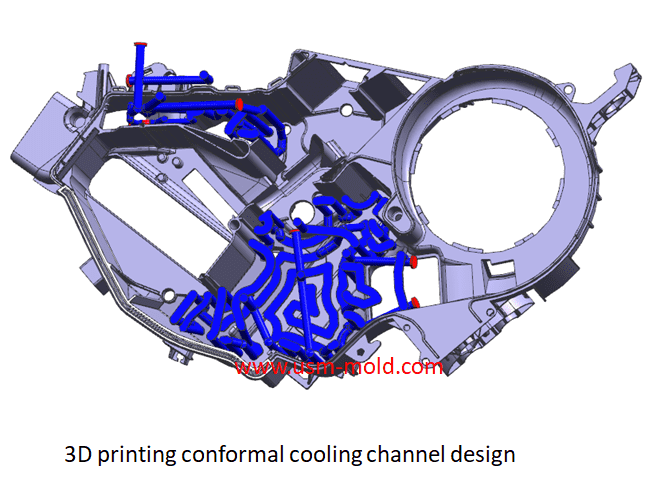

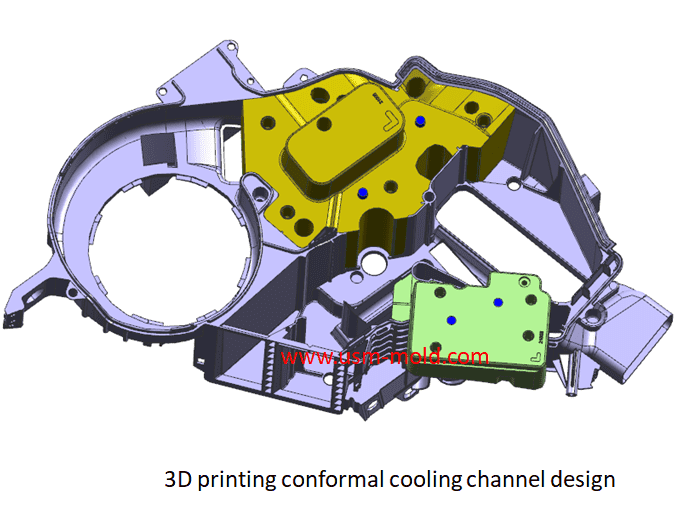

In many cases, injection molds need to be cooled, and the main way of cooling is to process cooling water gates in the mold, the main forms of cooling water channels are: straight-through water gates, circular water gates, heat-conducting water gates, diaphragm water gatesls, spiral water gatess and jet water gates. most molds are cooled by straight-through water gate in actual design, when the plastic parts shape is special, they are mostly cooled by a combination of straight-through water gates and other cooling water gates.

Factors should be considered when designing a temperature control system:

1. The wall thickness, projected area and structural shape of the molded plastic part;

2. Production batch of plastic parts;

3. The property of molded plastics;

4. The size and structure of the mold, and the insert parts;

5. The gate type and hot runner layout.

Banana gate of plastic injection mold runner system design

Feb 7, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

Pin-point gate of plastic injection mold runner system design

Jan 24, 2022In order to get the best injection quality, the gate type must be selected carefully, the coommon gate tyeps are: direct gate, side gate, pin-point gate, sub gate,valve gate of hot runner etc. Among...view

What is Ejection Molding?

Dec 28, 2021The process to get injection molded products is called injection molding, or called injection. Injection molding is an important method in polymer molding processing, it is characterized by a short...view

What is Called Draft Angle?

Dec 29, 2021The draft angle is also called demold angle and angle which is used for product removal from the mold and designed on the parting surface, the angle is called draft angle which shows in picture 1....view

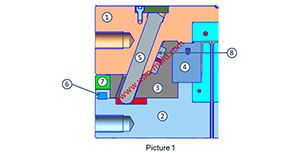

Slider of side core pulling mechanisum assembling

Jul 21, 2022The picture 1 shows a typical guide pin driven slider parting and core-pulling mechanism, we will talk about the composition and function of the lateral core-pulling mechanism. 1. Lateral forming...view

The main design points of the design of the plastic mold pouring system

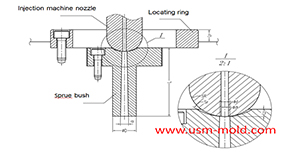

Jan 11, 2022The main runner is the part where the molten plastic first passes when it is sprayed from the injection nozzle, and it is coaxial with the injection nozzle, because of repeated contact and collision...view

English

English русский

русский

_20250310164515A048.webp)